In my quest to find the best soundproofing materials to use at home, I’ve spent a lot of time searching for alternatives to normal glass. As you may know, it’s one of the weakest areas for sound transmission, and I found this out the hard way when living in an inner-city apartment!

My search led me to the topic of soundproof plexiglass. As a transparent sound barrier, it has the potential to work alongside traditional glass. But to understand why, it’s worth comparing the two products.

So that’s exactly what I’ll do in this article. Read on to find out everything you need to know about plexiglass sheets vs. glass for soundproofing.

How Does Plexiglass Reduce Noise?

The best place to start is by defining plexiglass. It might be a term you’re familiar with, but there are a few different kinds within this main bracket.

Plexiglass is a plastic made from methyl methacrylate polymers. It’s transparent, shatterproof plastic sheeting that’s often used in place of traditional glass. Interestingly, it’s actually more transparent than glass. Its transmittance factor is 92% compared to 90% for glass.

In short, plexiglass makes up for a lot of the weaker points of traditional glass. This means it’s become popular in construction, especially because it’s much easier to shape.

There are 3 main types of window grade plexiglass that we’ll encounter when looking at soundproofing projects. These are:

- Acrylic. The most common type of plexiglass is acrylic sheet. In fact, the brand name Plexiglass (and Perspex) is an acrylic-based polymer sheet, as are Lucite and Acrylite.

- Polycarbonate. This is a different branch of polymer plastic sheets that contain carbonates. It’s lighter and more flexible than acrylic, but also stronger.

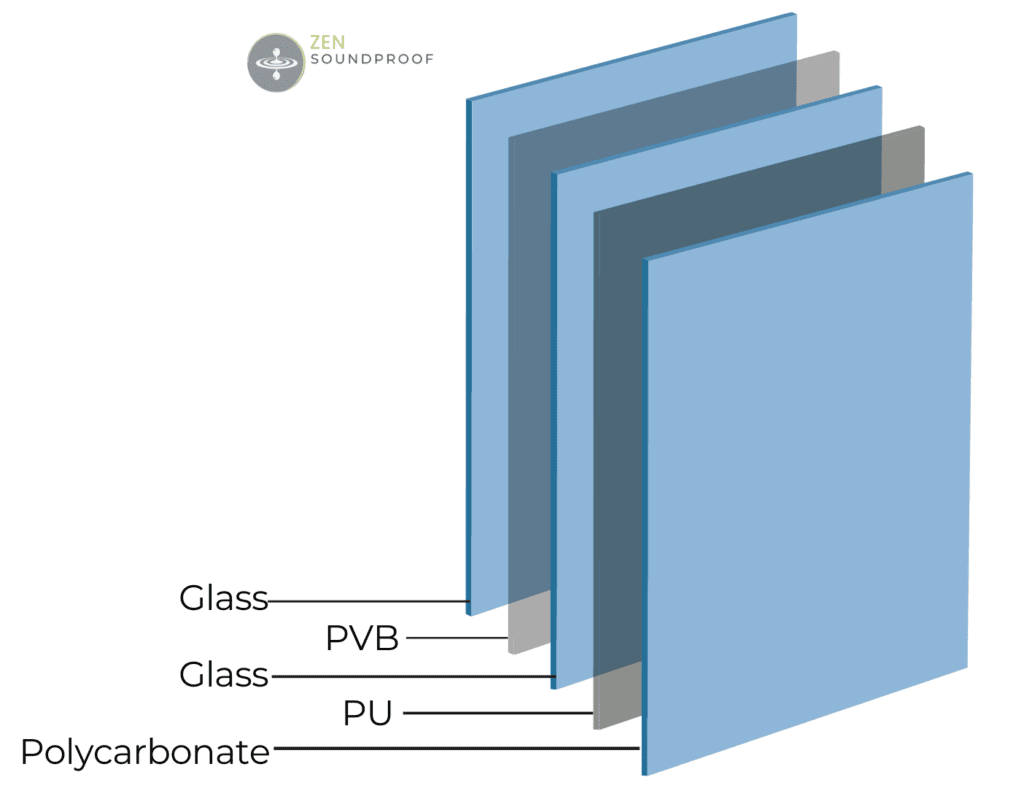

- Laminated. Like traditional glass, laminated plexiglass contains layers of different materials to improve certain properties. It might include glass, PU, UV-resistant materials, PVB, and more.

Because of its mechanical properties, plexiglass can help reduce sound transmission. Before looking at how, let’s recap the measurement we use for this.

Understanding STC

STC stands for Sound Transmission Class. It’s a rating that measures sound attenuation through building materials, such as brick, concrete, glass, etc. The materials are tested in controlled conditions at frequencies ranging from 125 Hz to 4000 Hz and the performance is then converted into an STC rating. Higher ratings mean better sound attenuation.

How Does Plexiglass Reduce Noise Transmission?

Plexiglass works as a sound barrier primarily by reflecting sound waves back towards the source. It’s less stiff than normal glass, and this gives it sound dampening properties too. To a very minor extent, plexiglass absorbs sound, but this is almost too negligible to matter.

As with normal glass, plexiglass isn’t a great sound barrier, at least compared to mass-rich materials like concrete or brick. We can directly compare the STC ratings of acrylic and polycarbonate with glass of the same thickness:

| Material | Thickness (inches) | STC Rating |

|---|---|---|

| Acrylic | 1/8 | 23 |

| 1/4 | 28 | |

| 3/8 | 30 | |

| Polycarbonate | 1/8 | 25 |

| 1/4 | 29 | |

| 3/8 | 34 | |

| Glass | 1/8 | 30 |

| 1/4 | 31 | |

| 3/8 | 34 |

Polycarbonate is more similar to normal glass than acrylic in terms of STC ratings. However, both score lower at every thickness. So why might we want to use plexiglass instead of normal glass?

Other than its superior construction properties, another key advantage is its different resonant frequency. Plexiglass doesn’t have the same stiffness as normal glass, meaning it’ll block and transmit different frequency sound waves. As such, it makes a good complement to normal glass rather than a full replacement.

Plexiglass vs. Glass for Window Soundproofing

I’ve already started to touch upon the main comparisons of plexiglass and glass. However, I always find that STC ratings should be considered alongside two more important metrics: cost and durability.

In short, if a material performs better in terms of durability and installation (especially for a DIY project), it might be worth considering. Similarly, cost is a bit more subjective, but there are numerous reasons why you might want to spend more on a soundproofing material.

So, let’s dive into it.

Plexiglass vs. Glass: Durability

Plexiglass is more durable than glass – this is its main advantage. It’s shatterproof and less prone to cracking and scratching. Bear in mind, though, that this depends on the material used. For example, polycarbonate is less scratch-resistant than acrylic.

It’s also more impact-resistant than glass, but this isn’t exactly a high bar! Acrylic is 10 times more resistant, and polycarbonate is 250 times more resistant.

This is a useful property to have, but not necessarily for soundproof windows. Unless you’re factoring in heightened security, traditional glass should have enough impact resistance for a standard household window.

It could be more important, however, for soundproof transparent surfaces in other applications. These might include room dividers, office walls, etc.

However, plexiglass does suffer from some downsides that come from it being plastic. These include static electricity buildup, which can be an annoyance at best or a hazard at worst.

UV light exposure can turn some plexiglass polymers yellow, including acrylic. However, it can take more than a decade of constant exposure, and many companies add UV light resistance to their products. Polyethylene is one of the plastics most prone to yellowing, and we wouldn’t use that here.

Plexiglass vs. Glass: Cost

At the most basic level, normal clear float glass is cheaper than plexiglass. According to Dillmeier Glass, plexiglass costs on average $10 per sq. ft., whereas tempered glass is $5 per sq. ft. Importantly, tempered glass is more expensive than regular glass due to the extra chemical treatment.

You can pick up plexiglass sheets of different thicknesses on Amazon. Prices vary depending on the size and number of sheets, but most sit below $50 for a 5-pack of acrylic sheeting. However, these are usually for crafting and sign-making and won’t be cost-effective for soundproofing windows.

Instead, you’ll want to look at places like ePlastics or even Home Depot. Wherever you look, though, plexiglass will be more expensive than normal glass material. It’s typically more expensive to produce and unless you’re looking at high-end, laminated glass, the price difference is immediately obvious.

Plexiglass vs. Glass: Which is Better?

This brings us to the question: plexiglass windows vs. glass windows, which is better?

While the obvious answer is probably glass, it’s not really as simple as that. For example, you’ll likely already have glass windows installed in the space you’re soundproofing. Would you rip them out to replace them with plexiglass? Probably not.

Instead, we should think of plexiglass as being complementary to normal glass. We could use it as an extra layer over a window (getting the best of both materials) or as the basis for a soundproof enclosure. Plexiglass is easier to work with for construction and has plenty of uses over normal glass, albeit in slightly more niche situations.

How to Install Plexiglass for Soundproofing

Provided you work carefully and methodically, installing plexiglass for a soundproofing project isn’t too difficult. The best tool for cutting will depend on the thickness of the plexiglass. The typical sizes we’re working with (1/4 to 3/8”) can be cut with a scroll saw or, in a pinch, a hacksaw.

Anything thicker than an inch should be scored to create a channel and then snapped to break the piece off. Bear in mind that it can take 20 or more passes with a craft knife to make a sufficient score in the plexiglass.

You have 3 main options for fixing the plexiglass sheeting over your existing windows. These are:

Option 1: Use Magnets

Magnets are the easiest. You’ll simply need to glue some small magnets to your window frame and the plexiglass sheet. This method allows you to remove the plexiglass as needed, which is a nice level of flexibility.

Option 2: Screw The Plexiglass to The Wall

The next easiest is screws. Cut your plexiglass to size and then drill holes through which the screws can pass. You’ll want to screw the sheets into the wall rather than the window frame, especially if it’s made from PVC. Again, drill pilot holes and finish by screwing the plexiglass into place.

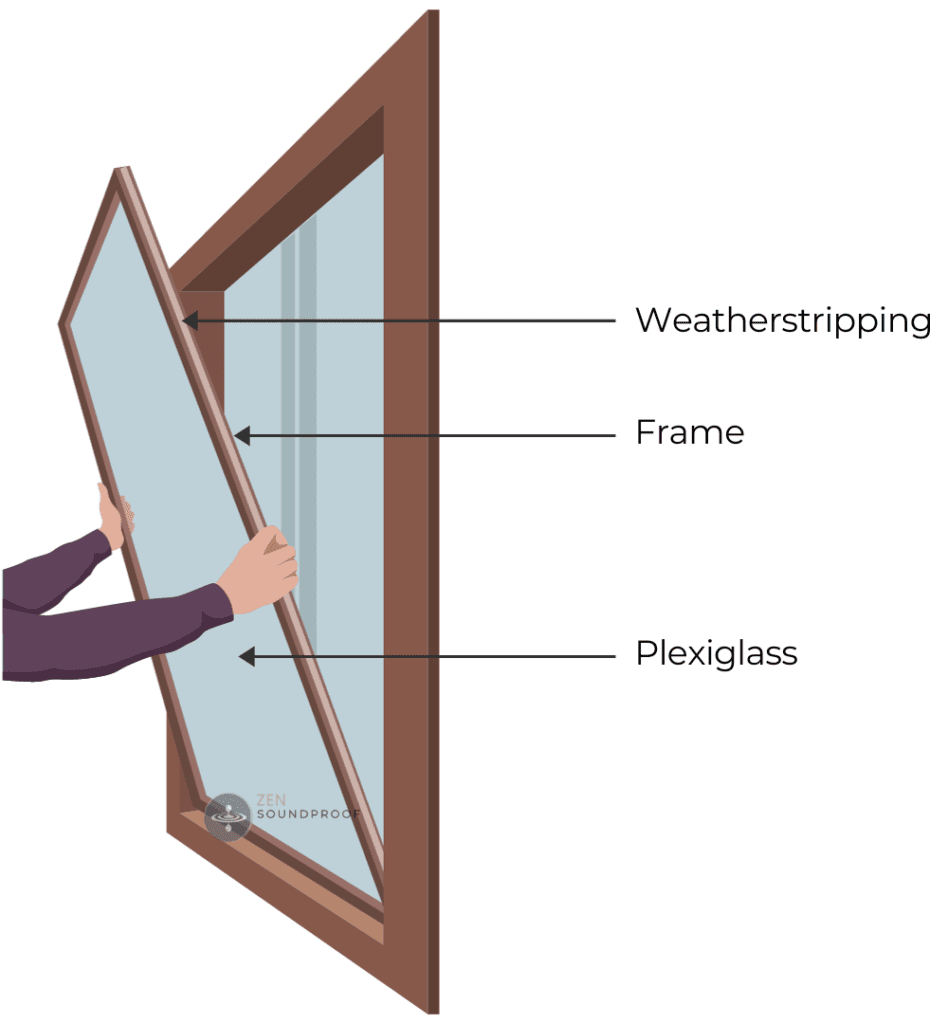

Option 3: Frame The Plexiglass as a Window Insert

Finally, you can frame the plexiglass. This basically makes window inserts, which are just as flexible as using magnets. Simply do the following:

- Measure the height and width of the window opening. Ideally, the window will be recessed slightly in the wall, giving you a gap to fit the frame into.

- Cut pieces of wood to fit and glue and nail together into a frame. You’ll want to make the frame around ¼” (5 mm) smaller than the window on each side, meaning there’ll be a gap. I’ll cover how to address this in the next section.

- Measure and cut your plexiglass sheet to fit this frame.

- Attach it to the frame using solvent glue.

- Fix a handle to the frame so you can remove it more easily, and then slot into place.

I recommend watching this video on DIY acrylic window inserts. It uses a slightly different method but it’s good for visualizing the end product.

Tips for Working with Plexiglass

Plexiglass isn’t an especially difficult material to work with. Even so, here are some of my top tips for ease of use that I discovered through trial and error.

- Wear goggles and a face mask. Cutting plexiglass can produce a lot of dust, and solvent glues aren’t great to breathe in!

- Plexiglass comes with a film coating. Leave this on the sheet until as late as possible to reduce the risk of scratching.

- Always use metal saw blades or cutting tools specifically designed for working with plastic.

- For cutting and drilling, work as slowly as possible. This minimizes the risk of cracking your plexiglass.

How to Improve the Performance of Plexiglass

There are numerous ways we can improve the base performance of plexiglass sheets, whether they’re acrylic or polycarbonate. Although I’ve taken these tips from working with normal glass, they’re just as applicable here:

Create an Air Gap

An air space is one of the best-performing components of double glazing. When insulating your window with plexiglass, make sure you leave an air gap between it and the existing window. The dead air adds an extra layer of acoustic and thermal insulation.

Seal the Edges

Sound waves can propagate through tiny gaps and easily pass from the plexiglass to the surrounding structure, or vice versa. To avoid this, seal the edges of the plexiglass sheet with weatherstripping, foam tape, or caulk. I recommend using weatherstripping to surround the wood frame in the instructions above, as this’ll help create a cushioned and tighter fit.

Choose Heavier Materials

Berger’s law (or mass law) states that every doubling of mass increases sound insulation by 6dB. While this is harder to achieve with plexiglass, the bottom line is that thicker and heavier materials will perform better.

Alternatives to Plexiglass

The main advantage of plexiglass as a soundproofing material is that it doesn’t sacrifice visibility. However, some alternatives offer superior noise blocking properties, or address different areas of soundproofing (such as absorption).

These include:

- Soundproofing curtains. Tackling noise from the inside, soundproof curtains help improve sound absorption within a space. They’re a better choice than window blinds, which don’t have enough mass to really make a difference.

- Window plugs. I’ve touched on this concept briefly above, but a proper window plug uses materials that can include mass loaded vinyl for superior sound blocking.

- Exterior shutters. While not especially mass-rich, you could line existing shutters with acoustic materials to improve their noise blocking and absorption.

While not explicit alternatives to plexiglass, you can also consider double-glazing and storm windows.

If you don’t already have double-glazed windows, installing them would be a better use of your time and money. Their noise-blocking properties are superior, especially if you use a layer of laminated glass.

Storm windows are similar, but a more temporary option. You could modify storm windows to include extra noise-blocking materials at the expense of letting in light.

Final Thoughts

I hope this article has helped you understand how plexiglass can help with soundproofing windows.

The bottom line is that plexiglass generally shouldn’t be a replacement for existing windows. Instead, it’s an ideal complementary product to help block different frequencies of sound.

Have you built your own plexiglass window inserts? I’d love to hear any tips you might have to help other readers design their own.