As an engineer, I’ve had the chance to work with many soundproofing products. And let me tell you, mass loaded vinyl (MLV) is one of the best out there! It’s a top choice for custom soundproofing projects.

But why is it so great?

Well, let me break down how MLV works to soundproof walls and why it stands out from other products.

What is Mass Loaded Vinyl?

Put simply, mass loaded vinyl is a custom-designed soundproofing product. As the name suggests, it’s made from vinyl that’s filled with dense compounds. We mainly use a viscoelastic material as the base, typically polyvinyl chloride. The dense compounds are either barium sulfate or calcium carbonate.

The bottom line is that MLV is very heavy for its thickness and size. I’ll explain it in more detail below, but this essentially means it’s an effective way to add lots of mass to a structure.

Properties of MLV

The compounds above provide MLV with the following useful properties for soundproofing:

Density

MLV has a density ranging from 0.5-2lbs. per square foot. Its thickness can also vary, but it’s common for it to be between 1/16 to 1/4” thick.

For comparison, standard drywall weighs around 1.6lbs. per square foot at 1/2” thick. As you can see from the table below, mass loaded vinyl is more than twice as dense.

| MLV | Drywall | |

| Thickness (in.) | 0.25 | 0.5 |

| Density (lbs/sq.ft.) | 2 | 1.6 |

Flexibility

Mass loaded vinyl is what’s known as limp mass. I explain this in the next section, but it essentially means it doesn’t transfer vibrations in the same way as rigid materials.

Mechanical Resistance

MLV has high tensile strength and tear resistance, meaning it’s an incredibly durable material. It has high mechanical strength (both tensile and tear), which is necessary because of its high density.

While these factors might not mean much to the average DIYer, they’re important metrics for any building material. They mean the material can sustain its own weight when hanging, even if you staple or nail it.

Also, you can apply further layers of materials to the mass loaded vinyl, such as more drywall.

Fire Rating

MLV is a flame retardant material. It is either certified safe to use for automotive installation via the FMVSS 302 standard, or safe for building installation via the ASTM E-84 class A rating.

The automotive and building code certifications ensure that material (in our case the MLV) has a low flame spread. Safety should be a priority, so make sure the MLV you buy has the right certification for car or building installation.

Odor

Generally, mass loaded vinyl is odor-free. However, some products can sometimes have a slightly plastic odor when they’re first unpacked. If this is the case, it’s usually because it’s an old product that’s been stored for a while. It should dissipate after a few days.

Usage

We use mass loaded vinyl to block sound from transmitting through a structure. Generally, it’s used as a sound barrier in home and automotive projects, although the product for vehicles usually has extra thermal insulation. Either way, they’re made from the same basic components.

Some examples of its use include:

- Wall and ceiling construction (e.g., home theater, recording studio)

- Wrapping around noisy pipes or ducting

- Soundproofing vehicle cabins (installing under bodywork)

- Installation under the vehicle hood for sound muffling

How Does MLV Work?

As mentioned, the main point of MLV is that it’s dense and limp mass. But what does this actually mean, and how does it help with soundproofing? Let’s cover a few definitions to break it down.

Limp Mass

Although it sounds quite technical, I often find limp mass is easy to understand. In short, limp mass is a material that doesn’t reflect sound waves in the same way as a rigid surface.

To go back to basics, sound waves are vibrational energy. When they come into contact with a hard and flat surface, a portion of the energy is reflected.

But if they hit a flexible material, the energy will be dampened. The material flexing causes the sound wave to dissipate through energy displacement.

Think of it this way: you’re bouncing a tennis ball. If you throw it at a brick wall, it bounces back to you very easily. Throw it at a bed sheet hanging on a washing line, however, and the ball will drop to the ground.

This is because its kinetic energy went into displacing the sheet, meaning the ball had no energy left to bounce off. It’s exactly the same principle for MLV, where the ball is the noise vibration and mass loaded vinyl is the bed sheet.

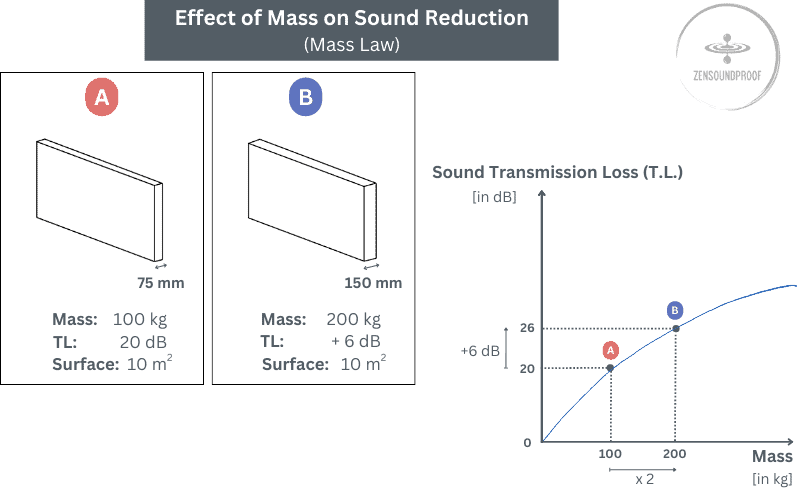

Berger’s Law

Mass Law (or Berger’s Law) is a foundational principle in soundproofing logic. It states that for every doubling of a material’s mass, we reduce perceived sound levels by 6dB. So, if we were to double a wall’s mass, sound transmission would be reduced by 6dB.

Mass is vital for noise barriers because it makes it more difficult for a sound wave to transmit through matter. In simple terms, sound waves are vibrational energy, and heavy objects don’t vibrate as easily as light ones.

Putting This Together

Combining these 2 principles explains why MLV is good at what it does. It essentially creates a sound barrier by combining density and flexibility. Sound waves hit its surface and aren’t reflected back into the space (dampening).

Any sound waves that are transmitted into the structure – such as from a neighboring room – can’t pass through as easily thanks to MLV making the structure harder to vibrate.

How Should MLV Be Installed for Soundproofing?

So, installing mass loaded vinyl is as simple as fixing it to drywall, right? Well, not necessarily. Based on my research, there’s a far more effective way to install it in your home, provided you can do the necessary work.

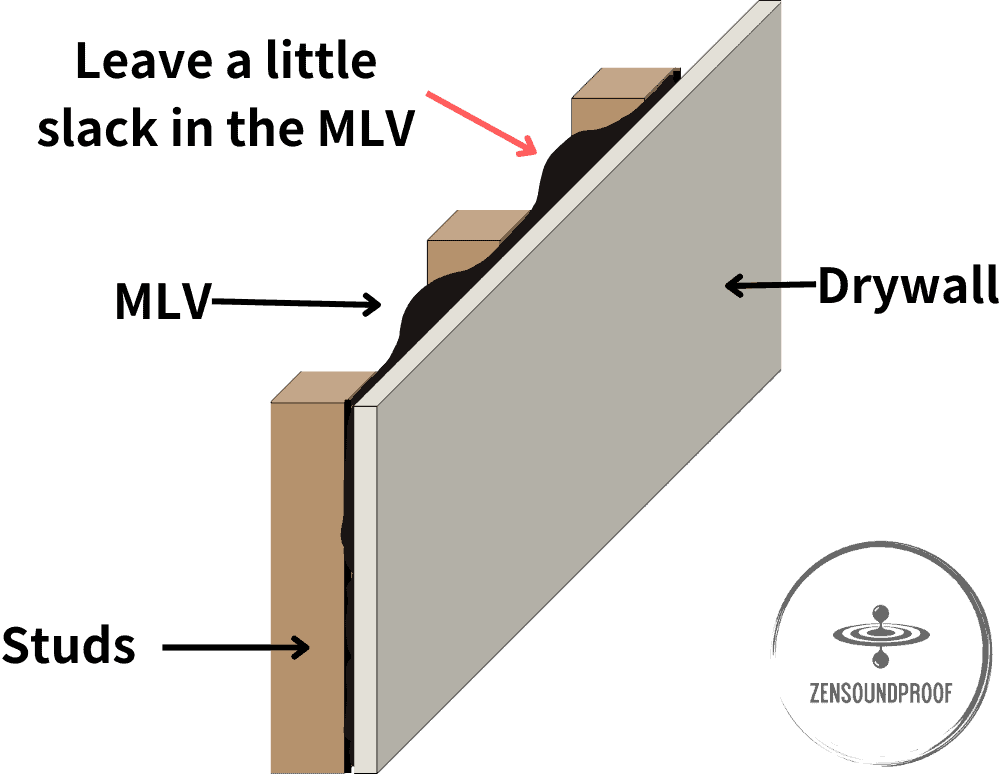

Taking full advantage of MLV’s properties

MLV is most effective at sound blocking when fixed directly to the wall studs with a bit of slack in the material. This setup allows it to move freely, meaning you get the benefits of its limp mass effect. The slack is to allow for sound wave dissipation via motion.

I recommend you to check my article about how to install MLV. It offers a decent visual guide for what I’ve explained above.

What to avoid

Fixing it directly to the drywall means you won’t get the limp mass effect, as the MLV can’t move freely. This is true regardless of whether you install it inside the wall or on the outer side of the drywall.

Of course, this isn’t to say you can’t install it on an existing wall. It just means that its impact will be more limited by comparison because you’ll only get the added benefit of extra mass. For its full effect, fit it to the wall studs.

Some important tips include:

- Your MLV still needs to be as airtight as possible. You can have an airtight setup that’s got enough slack – just don’t cover more or less than the surface of the wall.

- Use acoustic caulk to seal any gaps around the edges of the MLV. This is the most effective way of creating an airtight seal because sound energy can fit through even tiny gaps.

- MLV helps against both structure-borne (impact) noise and airborne noise. This is why it’s vital for you to get a decent seal around it.

For more specific information on how to get the most from this product, check out my article on how to install mass loaded vinyl on walls and ceilings.

STC Rating of MLV

As I’ve explained in detail elsewhere, Sound Transmission Class (STC) is a useful rating for working out a material’s ability to block sounds. We generally have standalone STC ratings for a material and then overall STC ratings for it as part of a structure setup.

As mentioned, MLV has different densities and thicknesses. While these measurements are correlated (thicker products have higher density), it’s easiest to view the information in the form of a table. The figures below come from Trademark Soundproofing’s MLV.

|

Thickness (inches) |

Density (lbs. per sq. ft.) |

Purpose / Uses | Standalone STC Rating |

| 1/16 | 0.5 | Pipes and curtains | 20 |

| 1/8 | 1 | Floors, walls, fences, etc. | 26 |

| 1/4 | 2 | Ceilings, walls, vehicles, etc. | 33 |

MLV with a density of 1lb. per sq. ft. is generally the most versatile and popular product. It strikes a good balance between thickness, STC rating, and ease of installation.

But to understand what this actually means, let’s look at some examples of wall assemblies with and without MLV. Again, it’s easiest to provide this information in a table.

| No MLV | With MLV | ||

|

|

||

| Wall Assembly | Starting STC | MLV Density | Final STC |

|

5/8” thick drywall, single 2×4 studs (16” oc) no insulation |

33 | 0.5 | 39 |

| 1 | 41 | ||

| 2 | 42 | ||

The wall assembly used here is one of the most basic you’ll find in a building. It uses standard drywall and stud assemblies and no cavity insulation. As such, the final results come from simply adding MLV.

As you can see, calculating STC ratings isn’t as simple as adding the figures together. It’s a logarithmic scale, much the same as decibels.

As such, we can’t really quantify noise reduction in a value of percentage reduction, as much of it comes down to how the individual perceives noise.

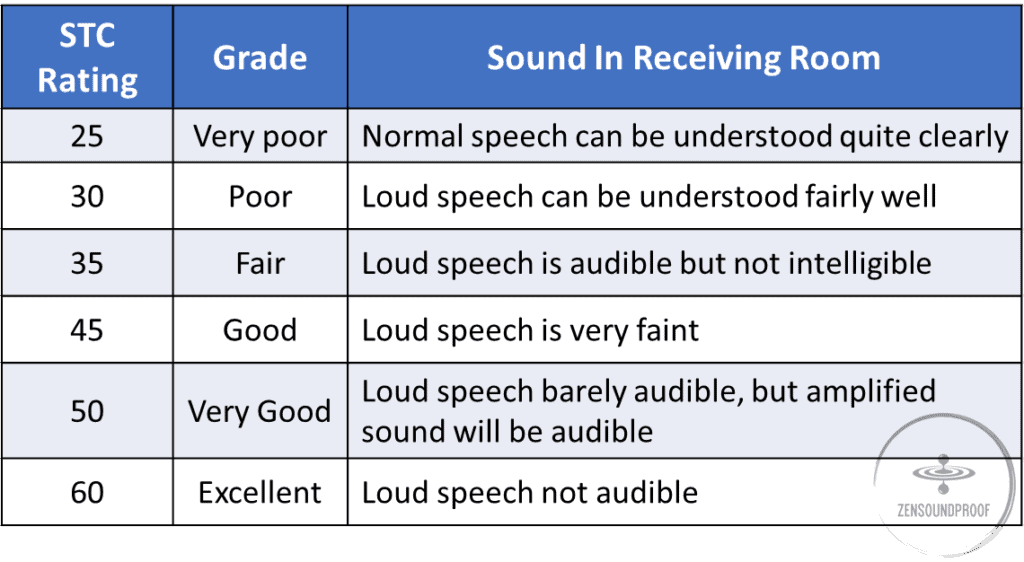

Look at the table below for a better idea of what STC improvements look like. An STC of 45 means some loud speech is barely audible (for example, muffled through a wall).

But when we increase to 50, which is the recommended value as per the International Building Code, loud speech isn’t audible at all.

You can boost the results of MLV by adding more materials. For example, you might want to use:

- A sheet of MLV on either side of the wall,

- Some cavity insulation (i.e. fiberglass or mineral wool),

- Acoustic caulk to seal gaps

This would result in a jump from an STC of 42 to 49. It’s a huge improvement as an STC of 50 is the target in building codes. The STC of 50 bar is what’s considered good for noise insulation, for instance you wouldn’t hear a loud speed in the adjacent room.

Cost: Is MLV Worth It?

If you’ve looked up mass loaded vinyl in the past, you’ll know it’s a pricey material. There are several reasons for this, including the production cost and the simple fact that it’s a small market.

I’ve listed some alternatives to MLV in a separate article. I know it will be useful if MLV is too expensive of an option.

While there are numerous manufacturers, there just isn’t the same supply and demand as more common products. In turn, it means they can charge quite a bit of money for it.

But this leads us to the question, is mass loaded vinyl really worth the price?

Let’s start by looking at a table of some average prices.

|

MLV Density (lbs. per sq. ft.) |

Area Coverage (sq. ft.) |

Average Price per Roll (USD) |

| 0.5 | 100 | 150 |

| 1 | 100 | 249 |

| 2 | 100 | 399 |

There’s no denying these prices seem quite high. For example, in a typical American bedroom with an area of 200 sq. ft., you’ll need at least 2 rolls of your chosen MLV. The cost can really start to add up when you look at it this way.

So, how does this compare to, say, adding more drywall to your structure? To understand this, we must look at the STC rating improvement of using these different products against the cost of each.

Cost Efficiency of MLV

To work out the sound isolation to cost efficiency, we’ll use the figures I’ve given above for MLV sound barriers. We’ll start with a baseline wall construction to see how much each type of MLV improves its STC value, and the cost it takes to do so.

| STC |

Cost (For 100 sq.ft) |

Cost Efficiency | |

|---|---|---|---|

|

|

39 | Baseline | Baseline |

|

|||

|

|

44 (+5) | 150 $ | $30 / STC gained |

|

|||

|

|

46 (+7) | 249 $ | $35 / STC gained |

|

|||

|

Fiberglass |

47 (+8) | 399 $ | $50 / STC gained |

|

|||

The calculation would result in a ratio of $30 per STC point gained for the lowest density MLV. It can cost up to $50/STC point for higher density MLV.

While $50/STC point is higher, it’s much closer to the bar of STC 50 without increasing the wall assembly thickness by much.

Cost Efficiency of More Drywall

Using the same workings, we can calculate figures for drywall. The cost per square foot can range from $0.40 to more than $90, but the average for the thickness and type we’d want to use is $2.25.

According to this STC calculator, a single additional sheet of drywall brings an assembly’s STC rating up to 42 from 39.

| STC |

Cost (For 100 sq.ft) |

Cost Efficiency | |

|

|

39 | Baseline | Baseline |

|

|||

|

|

42 (+3) | 225 | $45 / STC gained |

|

|||

|

|

44 (+5) | 450 | $90 / STC gained |

|

|||

Dividing the cost by the STC gain gives us a figure of $45-90 per STC gained, meaning MLV is a more cost-effective solution. While drywall is a more accessible solution, it’s objectively not the best option for noise reduction in a room.

As you can see, stacking more layers of drywall quickly reaches its beneficial limit.The gain is reasonably interesting when we stack an additional layer (STC +3) but another layer provides less gains (STC +2).

To reach an STC 50, how many layers of drywall would you need?

Too many.

Plus, you don’t want to end up with a wall that’s 10 times thicker!

Layers of drywall is a good example of why you can’t rely only on the soundproofing principle of mass (Berger’s law). You need to combine it with other soundproofing principles.

That’s exactly what we do in the next section.

Cost Efficiency of Green Glue

Finally, we should consider Green Glue Noiseproofing Compound. It’s used for sound damping and is a good addition to a wider soundproofing assembly.

Its rough cost is $0.75 per sq. ft. if you buy in bulk and it can increase an STC rating by up to 10 points.

| STC |

Cost (For 100 sq.ft) |

Cost Efficiency | |

|

|

39 | Baseline | Baseline |

|

|||

|

|

55 (+17) |

Drywall sheets: $450

+ Green Glue: 2 x 100 x 0.75 = $150 Total=$600 |

$37.5 / STC gained |

|

|||

This results in a cost of $37.50 per STC point gained when combined with a range of other materials. While not the best cost efficiency, it’s the first configuration that goes above STC 50 at a relatively acceptable cost.

In this case, we relied on adding mass (drywall), and sound damping (green glue). This demonstrates that mixing different soundproofing principles is necessary to reach high STC numbers.

When is MLV the Best Option?

So, is mass loaded vinyl worth it? To reduce noise transmission, an MLV sound barrier is a fairly cost-effective solution. Its startup cost looks high when you compare its price to that of drywall.

But, as you can see from the tables above, it works out as a better dollar-to-STC ratio.

If you want the best combination that blocks sound waves, you’ll need to use Green Glue too.

It coats the drywall sheets to provide sound deadening and can bring the STC value up to 55. This is above building code standards of 50, which will ensure optimal soundproofing performance.

Final Thoughts

That should cover everything you need to know about using mass loaded vinyl in a soundproofing project. The bottom line is that once you break down its cost efficiency, MLV is a great DIY soundproofing material.

Do you have any other recommendations for how to use mass loaded vinyl, or have you used it in a project around your home? Feel free to share your experiences below.