I’ve been interested in soundproofing for some years now, and one material regularly draws my attention more than anything else: glass. Regular glass is one of the weakest materials for blocking noise transmission, and I’m always after new solutions to change this.

That’s what led me to the subject of this article – soundproof glass. I decided to research soundproof glass to see if it can actually solve the problem of noise transmission and, if so, how best to use it.

Read on to find out what materials we use for soundproof glass panels, and how they work!

Soundproofing Basics of Noise Reduction Glass

Before jumping into the topic of soundproof glass, there are a few soundproofing basics we must cover.

Mass

Put simply, mass refers to how heavy something is. In soundproofing terms, an object with more mass is more difficult to vibrate, aiding sound reduction. We use Berger’s law in soundproofing, which states that the sound insulation of a wall increases by 6dB with every doubling of mass.

Unsurprisingly, glass typically doesn’t have a lot of mass, at least compared to brick, concrete, etc.

Mechanical Decoupling

In soundproofing, decoupling refers to the process of isolating one side of a structure from the other. For example, a normal partition wall consists of 2 layers of drywall with wood joists in between. Decoupling involves putting a manual break in this structure to stop sound waves from transmitting through.

We can do this with glass windows, too. For example, we might put a sheet of resilient material between the panes, or surround the window with rubber to separate it from the window frame.

Resonance Damping

A sound wave is vibrational energy that transmits through a structure or the air. Damping involves reducing this vibrational energy using diffusion. Essentially, damping materials don’t pass on vibrations, instead making them disperse their energy.

A real-world example is the shock absorbers in a car’s suspension system. They turn the up-down movement of kinetic energy into heat energy. Acoustic damping materials do the same.

It’s important to understand damping, as this is one of the most important principles involved in soundproof glass.

How Does Soundproof Glass Work?

Soundproof glass involves incorporating soundproofing solutions into the basic setup of a glass pane. For example, this could involve:

- Increasing the thickness of the glass (adding mass)

- Adding layers of resilient material between the panes (decoupling)

- Framing the glass panes in resilient material (damping)

- Increasing the space between the panes

The type of soundproofing we use will depend on the glass itself. In construction, we use any of the following 3 types of glass:

1. Clear float glass. This is “normal” glass. It’s a pane of glass with nothing else added during construction.

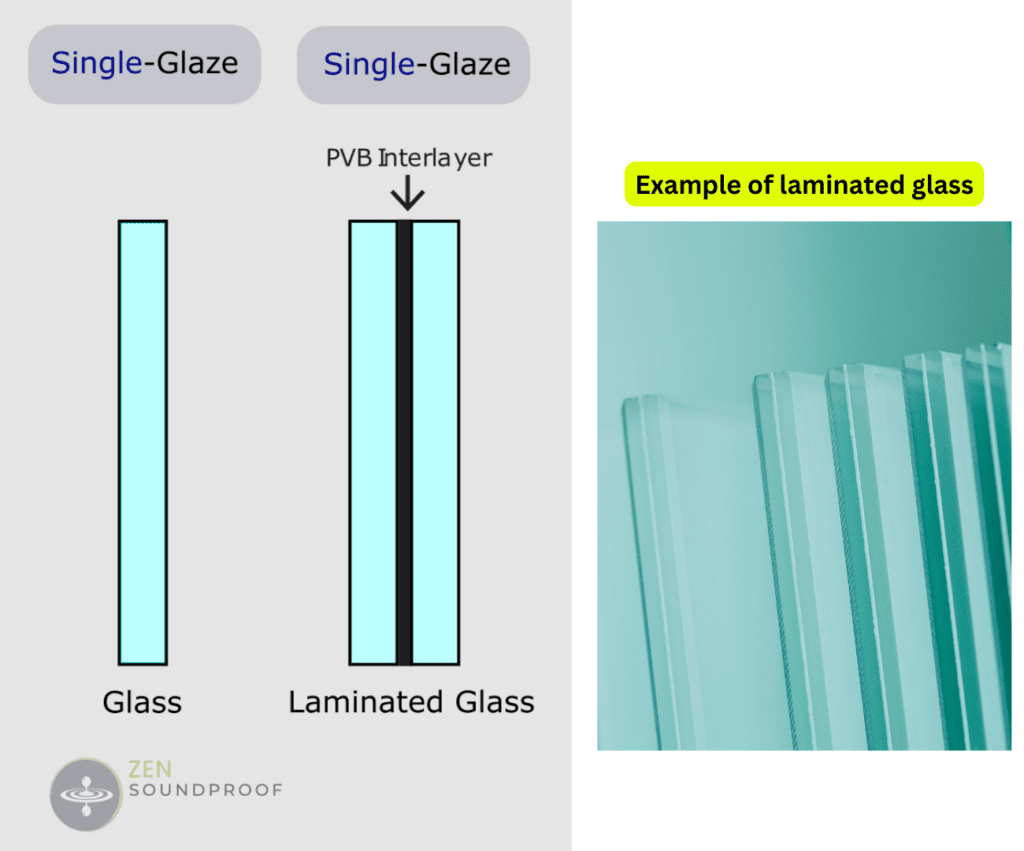

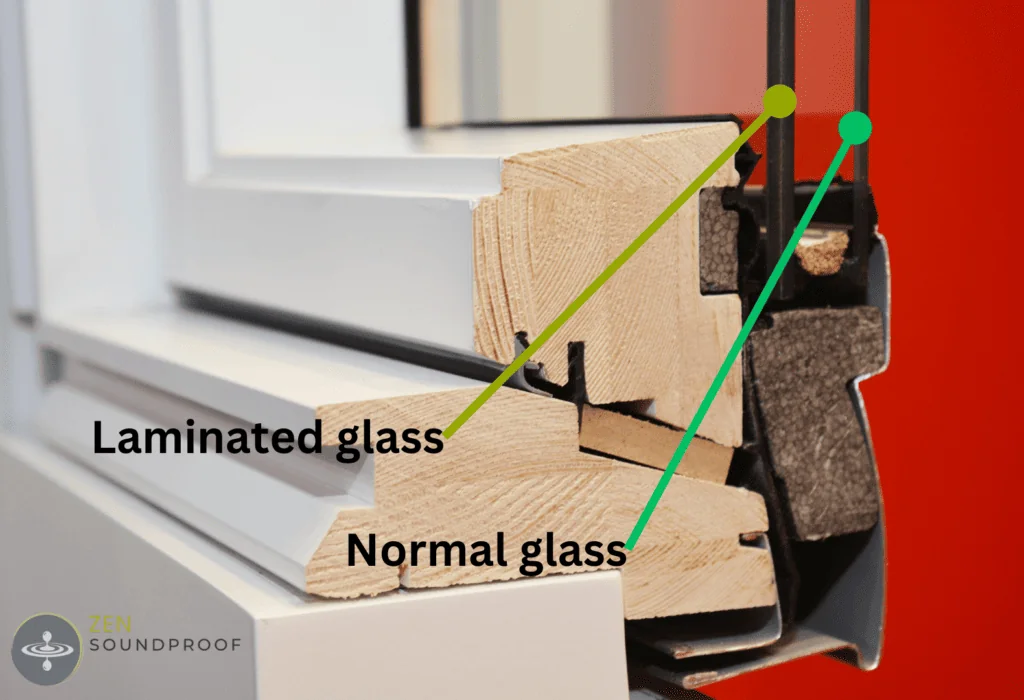

2. Laminated glass. Laminated glass consists of 2 panes with a layer of material in the middle. This is typically plastic polymers: PVB, EVA, TPU, or resin.

3. Tempered glass. Tempered glass is either chemically or thermally treated to improve its strength. Like clear float glass, it usually consists of a single pane rather than layers of material bonded together. It’s worth noting that tempering does NOT affect the soundproofing capability of a glass sheet.

Generally speaking, soundproof glass panes will be laminated glass. It’s worth knowing about the 3 main types of glass used in construction, though, as it’ll help you understand why laminated glass is best.

Using Plastic Laminates for Soundproofing

As mentioned, laminated glass has a layer of plastic that’s bonded to the glass sheets. The main purpose of laminated glass is to improve its safety by removing its ability to shatter. However, the plastic used as the middle layer has the helpful property of being a resilient material.

In soundproofing terms, this means it doesn’t pass on vibrations as well as rigid materials. The most common bonding layer used by glass manufacturers is polyvinyl butyral (PVB).

Said plainly, PVB is a plastic film, which is also a dampening material.

Importantly, too, laminated glass is thicker and heavier than other types of glass. As such, it blocks airborne noise better than other types based on the principle of mass.

In practice, soundproof glasses (or acoustic glass) can stack two or more layers of glass sheets with PVB in between. The more you stack, the better the soundproofing. You’re only limited by cost and installation space like the depth of a wall or window.

Using Multi-Pane Technology for Soundproofing

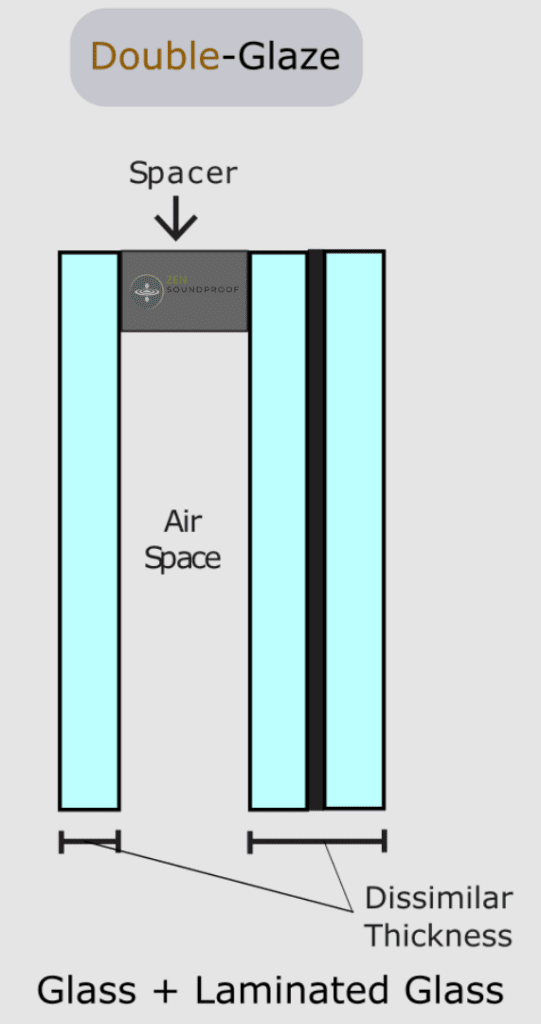

The other option available for soundproofing glass is multi-pane technology. As the name suggests, it consists of several panes of glass with an air or argon gap in the middle – double-glazing is an example.

An example of double-glazing would look like this: Clear Glass – Air gap – Laminated Glass

Air gaps help reduce noise transmission through the pane. Air is a poorer transmitter of sound than a rigid material like glass, and having sound waves pass through different media (air and glass) blocks different frequencies.

When combined with different thicknesses of glass, and plastic or resin layers, multi-pane technology can block a reasonable amount of sound.

Practical Applications of Soundproof Glass

Soundproof glass can be used in place of any normal type of glass. However, we may adjust the soundproofing technology, thickness of glass, and type of damping material depending on the specific application.

Some applications include:

- Windows. Windows may use thicker glass and larger air gaps to improve thermal insulation as well as acoustic insulation.

- Doors. The same is true for external glass doors, or internal glass doors between loud rooms (such as in an office).

- Skylights. Skylights won’t necessarily need the same kind of thickness, although this’ll depend on the location and the noise you’re blocking.

- Partitions. Glass partition walls may not have air gaps to reduce thickness and improve the appearance. Instead, we’d find layers of resilient materials.

The bottom line is that you’ll want to do some research on the best type of soundproof glass for your needs. Luckily, I’ve done some digging into the most important factors to consider, which I’ll cover below.

Choosing the Right Soundproof Glass

So, when we choose soundproof glass, we need to think about where we’re using it. For example, an external window in an inner-city apartment will need to block more noise than, say, an office door. Below are what I consider to be the most important factors when making your decision.

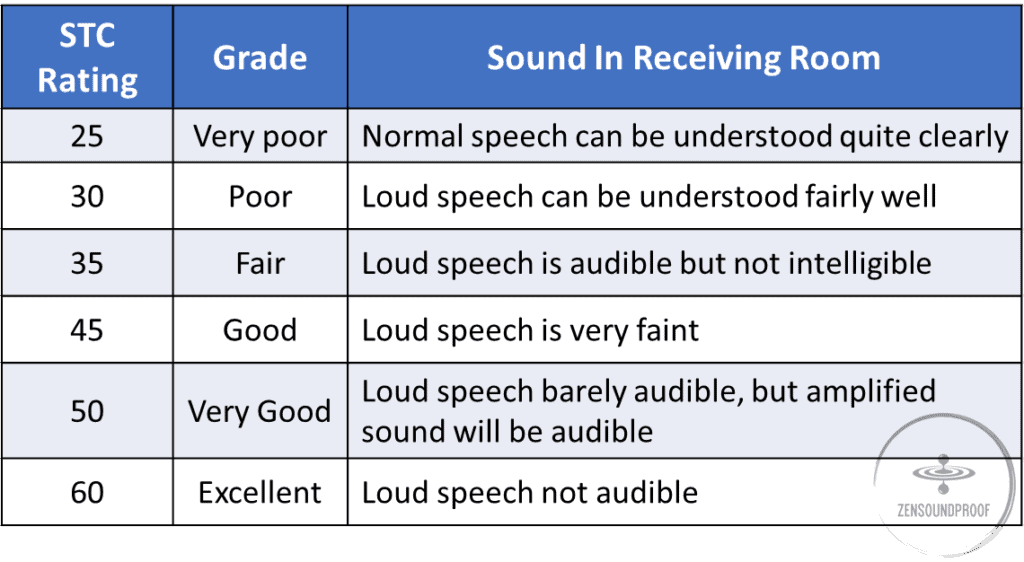

Check the STC Rating

I explain sound transmission class (STC) in more detail in my article about soundproofing a ceiling. In short, an STC rating measures, in decibel loss, the ability of a material to isolate sound. The higher the value, the more sound the material isolates.

OITC stands for outside inside transmission class. It works on the same principle as STC but specifically relates to exterior noise. This sort of noise pollution usually has more dominant low-frequency sounds (e.g., traffic noise) than interior-interior sounds (TV speakers).

STC ratings apply to frequencies between 125Hz and 4000Hz. OITC, on the other hand, measures 80Hz to 4000Hz to account for these lower frequencies. As such, it’s a more useful metric for soundproof glass because this is often used to reduce external-internal sounds.

Unfortunately, it’s nowhere near as common as STC ratings, so these are what you’ll have to use as your guide for decent soundproof glass. Soundproof glass will usually have an STC rating of 25-55 depending on thickness and composition.

Generally, noisier environments will need a higher STC rating. For example, an apartment near an airport or busy street will need to block more noise than a suburban home.

Consider the Glass Thickness

Thickness is an important metric for all types of glass, but arguably more so for tempered and float glass. Laminate and multi-pane glass will usually be thicker, but much of this space is taken up by the air gap or laminate layer.

Soundproof glass will usually measure between 1/8” and 1” for the actual glass pane. Some examples of glass thickness and STC (taken from General Glass) are:

| Glass Type | Glass Thickness | STC | OITC |

|---|---|---|---|

| Monolithic (single pane) | 1/4″ (6.4mm) | 31 | 29 |

| Monolithic (single pane) | 1/2″ (12.8mm) | 36 | 33 |

| Laminate (with PVB) | 1/4″ (6.4mm) | 35 | 31 |

| Laminate (with PVB) | 1/2″ (12.8mm) | 38 | 34 |

As you can see, an increase in thickness translates to an increase of STC and OITC ratings.

The nature of the glass also matters: at the same thickness, laminated glass is on average 4 points ahead in STC ratings than normal glass.

However, other factors like the number of panes and air gaps also have an impact on these ratings.

The Number of Panes

The number of panes is important for soundproofing because it provides more mass than fewer panes. Generally, the number of panes tops out at triple-glazing, but double-glazing is far more common. This isn’t a massive issue for soundproofing, as an Indow Window study found that triple glazing isn’t that much better than double glazing.

The table below shows the increase of STC ratings from single pane to dual pane. On average, there is a 4-point increase in STC values. But these values are also combined with the added air gap, which I’ll discuss further below.

| Glass Type | Glass Thickness | STC | OITC |

|---|---|---|---|

| Monolithic (single pane) | 1/4″ (6.4mm) | 31 | 29 |

| Dual Pane (with ½” air gap) | 1/4” – 1/4” (6.4mm – 6.4mm) | 35 | 30 |

| Glass Type | Glass Thickness | STC | OITC |

|---|---|---|---|

| Laminated (with PVB) | 1/4″ (6.4mm) | 35 | 31 |

| Dual Pane Laminated (with ½” air gap) | 1/4″ – 1/4″ laminated (6.4mm – 6.4mm laminated) | 39 | 31 |

There’s also a tradeoff between the number of panes and the cost and practicality of installation. More panes will cost more, and, as illustrated, the benefit may not justify this extra cost.

Instead, a far more effective solution is to use panes of dissimilar thicknesses. Panes of the same thickness will have the same resonant frequency, meaning the same sound will be able to pass through both panes.

The below table shows a 4 -point STC increase on average by changing the thickness of the second pane from ¼” to ⅜”, while the air gap remained constant.

| Glass Type | Glass Thickness (inches) | STC | OITC |

|---|---|---|---|

| Dual Pane (with ½” air gap) | 1/4” – 1/4” (6.4mm – 6.4mm) | 35 | 30 |

| Dual Pane (with ½” air gap) | 1/4” – 3/8” (6.4mm – 9.6mm) | 39 | 34 |

When panes are different thicknesses, they’ll have different resonant frequencies. This helps block more sound, as it works against more than frequencies. In the example above, it resulted in a 4 points STC increase.

Don’t Forget the Air Gap

The air gap between panes can help with the decoupling aspect of a soundproof window. Air is a poor transmitter of sound waves (at least compared to solid materials) because the molecules are farther apart.

The below table compares an air gap of ½” and 1”. The doubling of the air gap leads to an improvement of 2 STC points in that case.

| Glass Type | Glass Thickness (inches) | STC | OITC |

|---|---|---|---|

| Dual Pane (with ½” air gap) | 1/4” – 1/4” (6.4mm – 6.4mm) | 35 | 30 |

| Dual Pane (with 1” air gap) | 1/4” – 1/4” (6.4mm – 6.4mm) | 37 | 30 |

Larger air gaps are more effective than smaller ones, simply because there’s more decoupling space between the panes. Double-glazed windows have air gaps ranging from 6-20mm, although 16mm is most common. Soundproof windows have air gaps closer to 20mm, but can go as high as 22mm.

As with pane thickness, there’s a tradeoff between air gap size and practicality. A larger air gap will require more installation space, and may be more expensive due to the hardware required. Going for soundproof glass with the “standard” air gap of 20mm shouldn’t present any problems, though.

Other Considerations of Soundproof Glass

Along with the acoustic properties of soundproof glass, there are other benefits that justify installation. For example, soundproof glass helps improve:

- Security. Simply put, soundproof glass is thicker, and laminated varieties are much harder to break into.

- UV protection. Laminated glass has UV protection properties, another major benefit for use around the home.

- Energy efficiency. The air gap in double-glazed windows has effective insulating properties, especially when it’s filled with argon gas. However, laminated glass isn’t any better at thermal insulation than normal glass panels – it’s the air gap that provides this benefit.

Finally, we must consider the cost of soundproof glass. As mentioned, thickness and materials impact the price of soundproof glass – there’s a direct correlation between these factors.

Most companies will need to give you a custom estimate due to the various factors involved. However, a rough cost is $1,000 for a soundproof window, including installation. According to House Logic, this is the cost for a 3 x 5ft. window.

This is quite an expensive job, but the noise-reduction benefits compared to normal windows is fairly clear in the right environment. However, I’d advise instead looking at more budget-friendly options.

Soundproof glass is only really useful if you’re dealing with lots of noise or need a very quiet interior environment.

Instead, I recommend checking out my articles on how to soundproof a window and how to soundproof a sliding glass door. They offer solutions that, while not as effective, are much kinder on your wallet!

There are plenty of options for soundproofing windows that are much cheaper. For example, you could include a soundproofing material like mass loaded vinyl or use a sheet of acoustic foam.

FAQs

What type of glass is used for soundproofing?

Laminated glass is the most common option for soundproofing projects. The middle layer helps dampen sound waves. However, double-glazed windows can match the STC of soundproof glass and as such, can be a practical alternative for where you’re installing them.

How much does acoustic glass cost?

Acoustic glass costs around $1,000 per 3ft. x 5ft. pane, including installation. However, larger or more custom projects can easily cost in the tens of thousands! You can drastically reduce the cost by installing the glass yourself, but this obviously isn’t always an option.

Does soundproof glass work?

At ISO thickness, soundproof glass is superior to normal glass. However, most homes are equipped with double-glazed windows that already match the performance of a single pane of soundproof glass. As such, the immediate benefit might not be as obvious. Moreover, a double glazed window has better thermal insulation.

For optimal performance, I would recommend including at least a pane of soundproof glass in your double-glazed setup, provided cost is not a limitation.

Final Thoughts

I hope this article has clarified everything you might need to know about soundproof glass. The bottom line is that it can be quite effective against exterior noises, but it’s often not worth installing from a cost perspective.

Have you worked with soundproof glass before, or do you have first-hand experience of how well it works? I’d love to hear from you, especially if you’ve got advice for other readers.