When moving in my current place, one of the first things I did was to remove the carpet floor to replace it with laminate flooring. In this process, I went on a quest for the best underlayment for laminate flooring to reduce noise.

The underlayment plays a major role in thermal insulation, absorbing irregularities, and in soundproofing the floor from noises. But how to make the choice for the best soundproof underlayment?

This guide tackles the ratings to look at for an effective sound deadening underlay. It also presents the different materials depending on your type of floor.

Best Soundproof Performance

-

STC 73

-

IIC 74

-

ΔIIC 25

-

Thickness 2mm

Best Value for Money

-

STC 66

-

IIC 67

-

ΔIIC 21

-

Thickness 3mm

Budget Friendly

-

STC 66

-

IIC 64

-

ΔIIC Not specified

-

Thickness 2mm

Things to consider in a Soundproof Underlayment

The Soundproofing Capacity: STC & IIC

Airborne Noise

Airborne noise is the term used for sounds that move through air. Sound is a mechanical wave that needs physical matter (air) to travel. Without air, no sound. In the empty space for instance, no sound can be heard. There’s a famous horror movie quote: “In Space, no one can hear you scream”.

TV sounds, conversations, or the sound of a coffee machine are examples of airborne sounds.

STC Rating

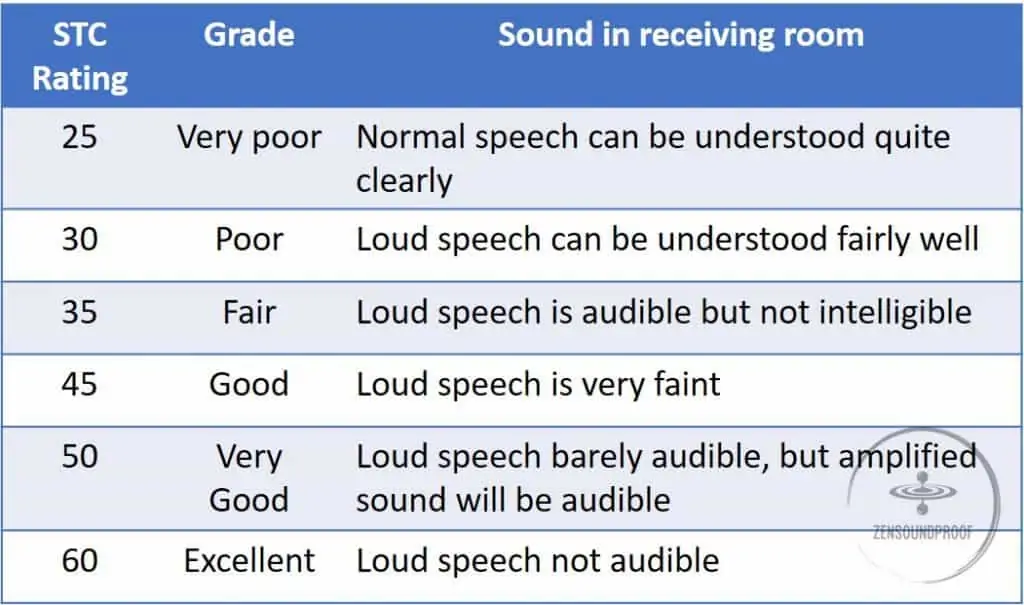

Soundproof underlays always display those 3 letters: STC. It stands for Sound Transmission Class.

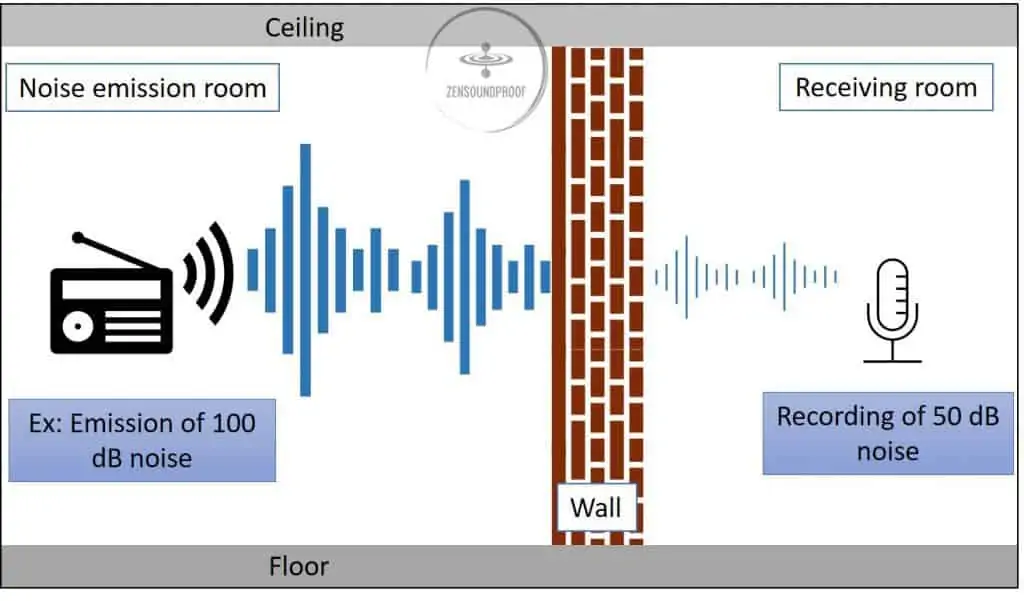

STC rating is a standard measurement determined in labs. It assesses how much a material can reduce airborne noise. This consists in measuring the loss in sound intensity (in deciBel) between two rooms. The material is used in the wall or floor that separates both rooms. The bigger the loss intensity, the better the material at noise reduction, thus a higher STC rating.

Building code requires wall or floor assemblies to achieve up to a STC rating of 50. Although not perfect, the STC is a good way to assess how much a material can block airborne sounds.

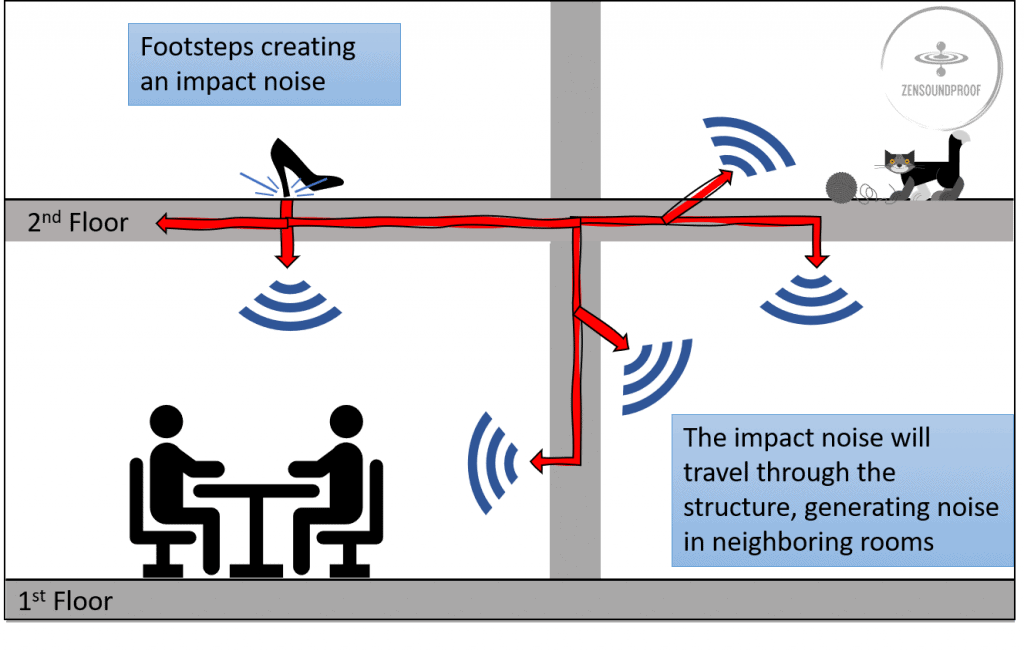

Impact Noise

Have you ever bounced a basketball or ran like crazy on a wood floor? At impact the ball, or footsteps, create a soundwave not only travelling through the air (as an airborne sound) but also travelling through the structure of the house.

That’s the main reason why you can still hear hammer strikes from your neighbor, while you can’t hear him talking.

IIC Rating

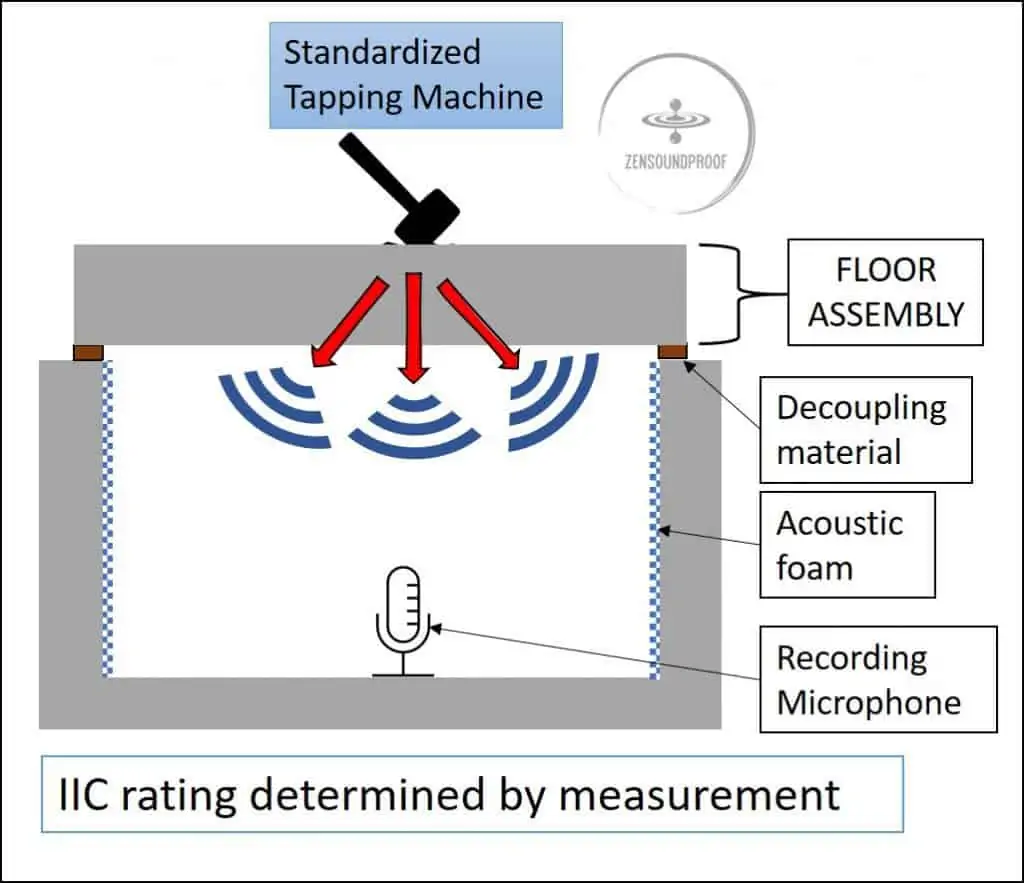

IIC stands for Impact Insulation Class (IIC). Said simply, the IIC is an equivalent of STC, but for impact sounds. It is determined in labs using a tapping machine in one room. In the receiving room, the sound levels emitted by the tapping machine are measured and then translated into a IIC rating. The higher the IIC value, the better the material dissipates impact noises.

Modern building codes generally require an IIC rating of 50.

Limitations of STC and IIC Ratings

IIC and STC in the way they are determined in labs, show the following limitations :

- The floor assembly composition in labs and in your home are not necessarily the same. The transmission of noise turns to be different from the lab testing to your floor.

- The floor assembly composition in lab testing from one manufacturer to another manufacturer are not necessarily the same. Thus, it becomes more difficult to compare values of STC/IIC between different manufacturers.

- IIC and STC don’t include frequency respectively under 100 Hz and 125 Hz. To have a better catch, here are sounds you can hear under 100 Hz : footsteps, traffic, aircrafts, construction machines, etc.

In my opinion, IIC and STC are necessary but they are not the only criteria to look at.

Delta IIC Rating: The Peacemaker

You might have understood that the floor assembly plays a major role in inflating the value of STC and IIC. It’s legitimate to ask ourselves, what is the pure performance of the underlayment alone.

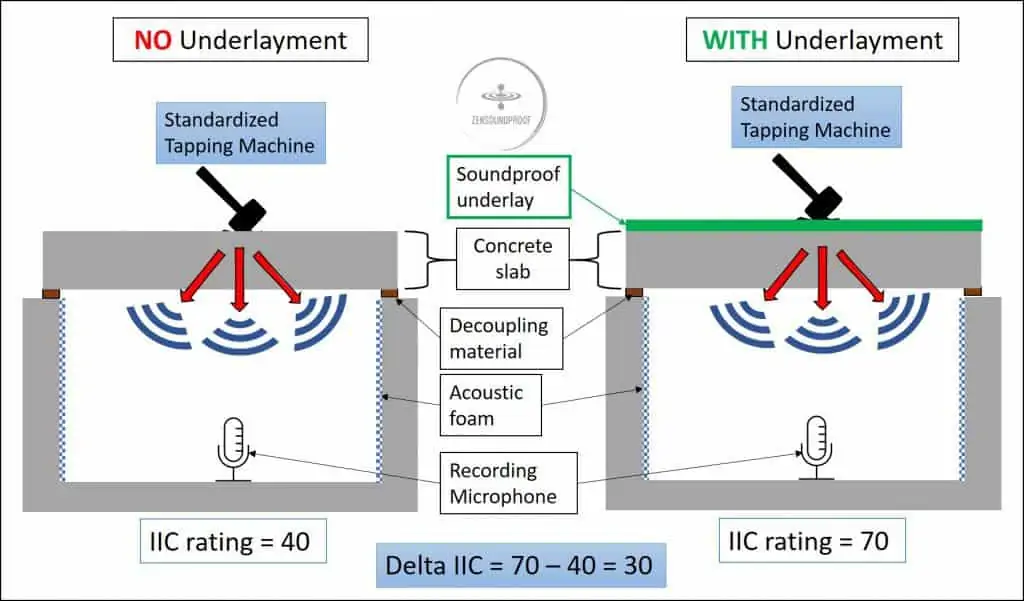

Take the time to picture the two following steps :

- Take a bare concrete subfloor with NO underlayment. Then measure IIC.

- Take the same concrete subfloor WITH underlayment. Measure IIC.

The difference of IIC between 1) and 2) is the Delta IIC. This test gives away the acoustic performance of the underlayment alone.

The delta IIC doesn’t depend on the floor assembly used during the manufacturer’s lab tests. Those lab tests generally use floor assemblies that are “under steroid”. A “strong” floor assembly means a better STC and IIC rating. This is flattering for an underlayment’s advertisement but not explicit of its sound insulation performance.

Generally an expected Delta IIC is 21 for a resilient material like foam, fiber or cork.

Types of Soundproofing Floor Underlay

To consider the right soundproof floor underlay for you, it is important to define the followings:

- To block airborne noise or to deaden impact noise?

- What type of flooring over your underlay?

For Impact Noise: Use resilient underlayment

Most floor underlays are resilient materials, making them the most effective against impact sounds. The material will absorb and reduce soundwaves at mid and high frequency. Resilient materials are not very dense, nor thick. But they introduce a decoupling effect which will help dissipate the sound energy propagating through your home structure. For example, rubber, foam, fibers, and cork are resilient materials.

For Airborne Noise: Use solid underlayment

Heavy and thick. Those are the two main characteristics that will make your floor block airborne noises. Good sound blocking materials are OSB (Oriented Strand Board), MDF (Medium-Density fiberboard), cement board, or Mass Loaded Vynil (MLV).

To address low frequency sounds like bass music sounds, I would recommend adding a damping compound. The Green glue damping compound does a good job. To be effective, It needs to be applied between two stiff layers (like 2 OSB boards for example). Everytime the two layers are excited by a sound, the wave will be absorbed by the glue and converted into heat. Check more about this solution here.

The Types of Flooring

What flooring underlayment to choose depends on the type of flooring.

- Under Carpet floors

For a carpeted floor, the carpet underlay material (also called carpet pads) that would fit the best would be foam, rubber or felted fibers. The US Department of Housing and Urban Development (HUD) has set carpet padding recommendations for residential applications. The requirements are available here. It might be a good idea to check those specifications with your retailer when prospecting for a model of carpet padding.

- Under Hardwood or Laminate floorings

Almost any type of underlayment works. From foam to rubber to fibers to cork, any underlay is a good fit as long as it’s in line with the manufacturer’s use recommendations. Depending on the humidity of your floor, you might consider an underlay that integrates a vapor barrier to protect your floor from humidity

- Under Vinyl, Tiles

Not all underlays fit a Vinyl, or Tiles type floor. While rubber can cause stain, Cork is always a good fit. Foam and fibers underlays are compatible depending on the manufacturer’s recommendations. Indeed some foam and fibers underlays are compatible, some are not.

Now you understand everything about the logic behind soundproofing a floor. Here’s a list of effective soundproofing underlayments for all types of floors with their pros and cons.

Our 5 Best Underlay for Soundproofing

1. QuietWalk Plus

- For use under: Laminate / Engineered Wood / Solid Wood / Rigid Core Vinyl / WPC / SPC / LVT (5mm or thicker)

- Subfloor : Concrete / Wood Subfloor

- Installation over subfloor : Floating / Glued / Mechanically Fastened

- Material : Recycled Fibers

- Thickness : 3mm

- STC: 71 – IIC: 66 – ΔIIC: 22

- Technical data: Check here

QuietWalk Plus is a very good option when it comes to absorbing impact sounds. I like its polyvalence as it can be applied under almost any type of flooring (laminate, LVT, etc.). I generally like to look at Delta IIC as it’s not a rating dependent on the floor assembly used in testing. Here the QuietWalk Plus gets Delta IIC of 22. This is better than most resilient material (generally Delta IIC of 21).

It has an attached vapor barrier.

However, we could complain that it’s not easy to cut, but it’s still easier than some of its competitors.

Because of the quality of construction, the great IIC rating, and the value for money, I would definitely recommend QuietWalk Plus.

- Good quality of construction

- Good sound dampening properties

- Vapor barrier

- Can be used under almost any floorings (except ceramic tiles)

- Difficult to cut

2. Roberts Super Felt Underlayment Premium

- For use under: Laminate / Engineered hardwood floating floors

- Subfloor: Concrete / Wood subfloor

- Installation over subfloor: Floating / Glued / Mechanically Fastened

- Material: Recycled Fibers

- Thickness: 3mm

- STC: 66 – IIC: 67 – ΔIIC: 21

- Technical data: Check here

This soundproof underlay is very standard. Roberts Super Felt Premium has the sound absorbing properties you would expect from an acoustic underlay (Delta IIC 21).

However, the quality of construction is not homogeneous. Two rolls of the same product might present differences in dimensions (thickness, width, length). Length and width dimensions can go off from the nominal dimensions by a few inches. The size can be adjusted, but this material is not easy to cut.

The vapor / moisture barrier has to be handled with care as people reported it is easy to tear down.

I would recommend this product if price is the main criteria for your flooring project. The price per square foot is around 20% cheaper than most of its competitors.

- Sound dampening properties will do the job (Delta IIC 21)

- Vapor barrier

- Price gives good value for money for a resilient material

- Dimensions are not very robust compared to nominal dimensions

- Difficult to cut

3. Natural Cork Underlayment

- For use under: Laminate / Engineered hardwood floating floors

- Subfloor: Concrete / Wood subfloor

- Installation over subfloor: Floating / Glued / Mechanically Fastened

- Material: Recycled Fibers

- Thickness: 3mm

- STC: 66 – IIC: 67 – ΔIIC: 21

- Technical data: Check here

This natural cork underlayment is very good material to work with. It is twice thicker than the previous material reviewed. So, take time to consider if 6mm could be an issue in your flooring project. The benefit of being thicker is it’s more effective in absorbing floor irregularities.

As a soundproof underlayment, natural cork does a good job at dampening impact sounds. You get a Delta IIC of 22, which I consider as a good rating.

Also cork has good thermal properties, it will help you reduce thermal transmissions. But one of the drawback is the absence of vapor barrier.

Installation-wise, the cork crumbles if not handled with care. So you need to consider some losses. However, it is easy to cut through and assemble.

I personally like the feel in hand of the cork material. Although it’s more expensive than the fiber based materials, it is an easy to work material.

- Good sound dampening properties (Delta IIC 22)

- Good thermal insulation

- Easy to cut and to install

- No vapor barrier

- More expensive than classic fiber and foam based acoustic underlayment

4. FloorMuffler UltraSeal Underlayment

- For use under: Laminate / Engineered / Solid Hardwood flooring Systems

- Subfloor: Concrete / Wood subfloor

- Installation over subfloor: Floating / Glued down / Mechanically fastened

- Material: foam

- Thickness: 2mm

- STC: 73 – IIC: 74 – ΔIIC: 25

- Technical data: Check here

The FloorMuffler UltraSeal is the soundproof underlayment with no concession. Although thinner (2mm) than its competitors, it has better sound absorbing properties. For instance, all the rating exceeds its competitor. The delta IIC of 25 is great. It also includes a vapor barrier. The installation is easy. There is no real downside with this material.

My opinion is that it’s not a lot more expensive for a true gap in quality and ease of installation. Among all the products reviewed this one offers the best acoustic rating performance. It’s fair to say it’s the best underlayment for laminate flooring for noise reduction.

- Best acoustic performance on the market

- Thin (2mm)

- Vapor barrier

- Polyvalent. It fits most types of flooring. (see note below)

- More expensive

Note: For Luxury Vinyl Tile and Plank flooring (LVT, LVP), FloorMuffler proposes an alternate solution. It includes the same features and acoustic properties.

- Technical data: Check here

5. 3in1 Silent Vapor Barrier

- For use under: Laminate / Engineered floating floor

- Subfloor: Concrete / Wood subfloor

- Installation over subfloor: Floating / Taped

- Material: Foam

- Thickness: 2mm

- STC: 66 – IIC: 64 – ΔIIC: TBD

- Technical data: Check here

The last soundproof underlayment of our review, is the budget friendly option. This material has almost all the qualities of its competitor. It includes a vapor barrier. It has an IIC of 64 (no delta IIC is communicated even after I asked the manufacturer) and it’s easy to cut and install.

My opinion : the sound absorbing properties are slightly under its competitor. But it delivers the same on all other aspects. If you’re tight on budget you should consider this material. Bear in mind that the price is dragged down because ordering comes by 10 rolls of 100 ft² (square foot). Also I believe the cut in costs might come from the little advertisement effort. (For instance specification sheets were not as exhaustive as its competitors).

- Sound dampening properties are ok

- Easy to install

- Vapor barrier

- Price

- Need to order big quantity

- Little technical information from manufacturer

Verdict: Best Underlay for Soundproofing

As you might have understood, your choice will come down to:

- The type of floor (wood floors, laminate flooring, tiles, LVT, carpet, etc.)

- Your needs (airborne, impact, vapor barrier, etc.)

- And your budget

My personal preference goes to 3in1 Silent Vapor Barrier for the rooms with lower traffic like a guest room, a storage room, or a dressing room.

However for higher passage frequency, I would not hesitate to spend a few more for the living room, the kitchen, or the kid’s bedroom. Thus, I would go for FloorMuffler UltraSeal. It is by far the best underlay for soundproofing.

Remember whether if it’s a wall, floor, or ceiling, the sounproofing principles always apply. I hope this guide helped you in your quest for a quieter home.

Thank you for reading,

Peace & Zen-up

11 thoughts on “Top 5 Best Underlay for Soundproofing: For All Floor Types”

This is the best document I have seen regarding underlays for Soundproofing floors. I have a question. I believe adding a good impact underlay will take care of the problem we are experiencing with a small 4 unit condo facility where two units are up and two units are down. The airborne noises were mostly eliminated with my replacing all the insulations (sides and ceiling) in my ground level condo unit. The unit above me plans to add new flooring to their place. I have volunteered to pay for the underlay including installation. However one of the impact noises that drives me crazy is the sliding patio door. It is very loud in my place. Is there a way to silence that sliding door? Thank you so much for your expertise and willingness to share.

Hi Carolyn,

Glad you like the article and find it helpful.

Nice of you to invest in your neighbors’ underlay 🙂

Going into your question, unfortunately, there’s no simple way to quiet a sliding door. I’d recommend checking the rollers and how healthy they look. Lubrication on the rollers and track can’t hurt. Is the rail still straight and clear of dust and debris?

The noise from the sliding door can resonate through the ceiling and wall cavities. Those resonancies can be prevented with sound absorbers like cellulose or fiberglass in cavities but I guess it’s an expensive solution.

If annoying noise come from the sliding door being shut, installing a damper can be an option.

Riddle me this, Batman.

The latest rage over the past few years in flooring is SPC (or WPC) planking, and the vast majority (besides Lumber Liquidators) of it comes with a 1-1.5mm layer of sound-absorbing foam (IXPE) attached. The problem is that the manufacturers will void your warranty if you put another sound-absorbing underlayment layer underneath it because it will interfere with the click-lock mechanism. I live in a high rise condo building with concrete flooring. Will that 1.5mm layer of sound-absorbing foam be enough to give suitable sound proofing to the unit below? Yes, the problem is that the lab ratings for these materials takes into account a 6″ slab with a 1 ft. drop ceiling filled with sound absorbing insulation. All we have is concrete between floors. Ideas?

Hi Ran, if you’re lucky your flooring and its thin layer of foam come with an IIC rating. Although not perfect (unlike the Delta IIC), it can give you a rough idea of where it stands compared to underlays.

In my opinion and as far as my experience goes, I’ve never seen anyone claiming their warranty after an issue on their flooring.

So If you’re overly concerned by the soundproof performance of your WPC and you need to stick with it, then maybe you should add an underlay.

Does your downstairs neighbor have a history of complaining about noise?

If you could access the room below, you could test different solutions just by testing different configurations of tiles ( with WPC & underlay Vs. WPC only). No need to install the tiles, one person stays upstairs and stomp, while one person is downstairs listening to the noise.

I hope it helps,

The condo with concrete floor problem is on point for me. Our condo minimum requirement for sound transmission insulation is equivalent to 31 ounce combination padding -or – 3/8″ foam padding -or- 80 ounce foam rubber padding. This is true for carpet or vinyl floor covering. If I decide to use wood, then the minimum is 1/2 inch plywood plus 1/4″ cork – or 5/8″ plywood plus 1/8″ foam that is set with a minimum of 1/8″ mastic on both the top and bottom surface.

The flooring stores say that these requirements do not take into account more recent insulation products.

I cannot find STC or IIC ratings for the above requirements.

Please advise. And I hope I remember where I posted this questions so I can see your answer.

Hi, thanks for the question.

I’ve been looking for technical data that would be equivalent to your condo minimum requirement.

Unfortunately, I couldn’t find anything perfectly matching what you described.

Instead, I would advise taking the ICC G2-2010 (International Building Code regulation) as a reference. It says the STC and IIC of your floor assembly should be 50 minimum.

In practice, if you take the above QUIET WALK PLUS and look at its technical datasheet, its lab results are as follows:

– STC 50: laminate flooring (7mm) + {6″concrete slab & no ceiling assembly}

– IIC 55: laminate flooring (7mm) + {6″concrete slab & no ceiling assembly}

You can do the same comparison exercise with any of the products listed above.

I hope this helps.

Am a little surprised you didn’t mention that rubber outperforms cork, especially at 1/4″ thickness. The other advantage of rubber is that it doesn’t dry out and harden like cork. Think of the cork in an old wine bottle. The wet end is pliable. The end opened to the air is much drier and tends to crumble.

I lived in the condo, the downstairs neighbor Always complains the noise. For the soundproof, could I put a underlay over my solid wood floor, and add a rubber roll over the underlay? As a middle layer, do you recommend the underlay is QuietWalk or FloorMuffler? Thank you.

Hi Mik,

I suppose you want to reduce impact noise. I’m not sure I understand correctly your question. If you want to use an underlay, it’s best if you use it below a flooring option.

In theory, if you put an underlay above a flooring it means you should stack another layer of flooring (laminate, vinyl, etc.). It’s just like building a floor on a floor.

If you know the areas you want to reduce impact noise, I’d suggest putting some EVA foam pads.

I hope it helps,

Ludovic

Yes I am trying to build a floor on a floor for reducing the impact noise. I don’t like carpets & foam. That’s why I will use the rubber floor. Thank you so much for your help.

Hello Ludovic! Your site has been incredibly helpful and informative. Could you offer a recommended resource on carpet pad specifics, or a recommended pad for beneath a new carpet installation? It looks like the link you gave to findanyfloor in here is dead now unfortunately.

I’m renting on the 2nd of 2 stories in a unit with hardwood floors. Building management has agreed to install carpeting over the hardwood with the goal of dampening sound from the unit below. Acoustic sound through the floor in particular has been the problem. It comes through pretty bad, even at very reasonable speaking volumes. I just want to work with the contractors to make sure we do it right.

I understand it may be intended for use under laminates and hardwoods, but is there any benefit to an underfloor layer like FloorMuffler going on top of the wood and beneath the carpet pad, for instance? Anything else we might look at? Thank you so much for any additional thoughts you may have!