Knowing how to soundproof vents in your HVAC system can help reduce those annoying noises that travel through ductwork. Provided you’re willing to do a bit of DIY, you can reduce noise in air vents quite a bit.

In this article, I’ll suggest some options for how to soundproof air vents. If you’re in a rush, here’s a summary:

- Line Ductwork with Acoustic Foam

- Cover Transfer Grilles

- Use Flexible Ducting

- Clean Vents and Ductwork

- Build a Sound Maze

- Check Your Return Vents

- Build Soffits

- Call a Professional

- Install a New HVAC System

Before digging into these further, it’s worth covering some technical information so the solutions make more sense.

Understanding the Types of Air Vents

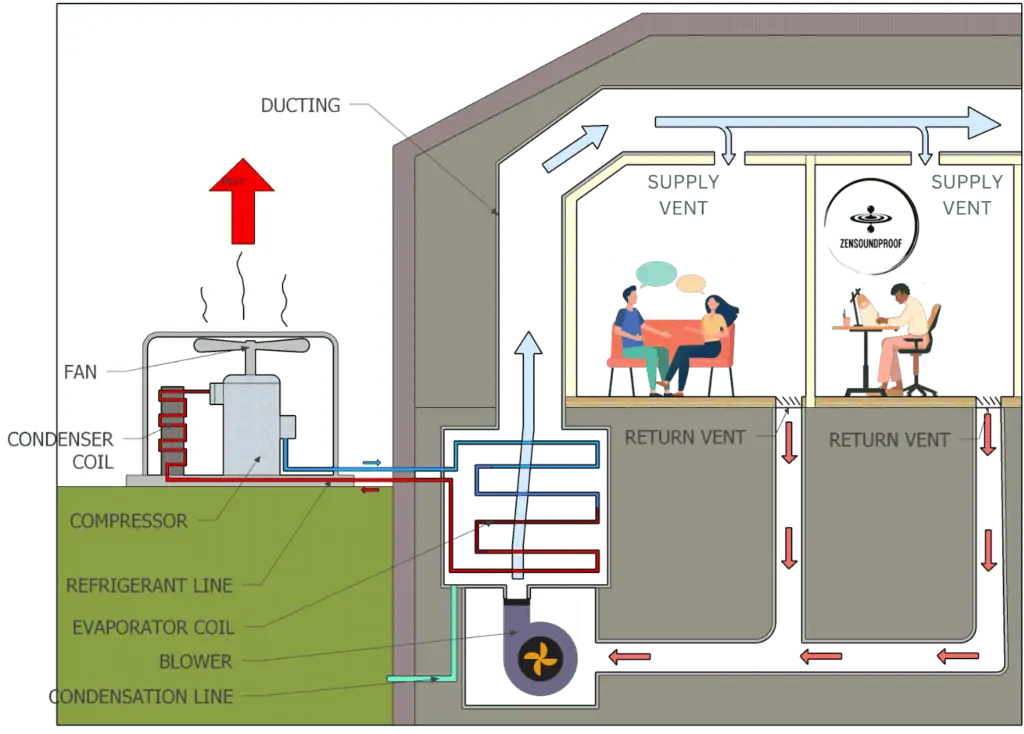

An HVAC system essentially has 2 types of air vents, which are:

- Supply air ducts. This is what supplies cool air to your room from the AC unit.

- Return air vent. These are the vents that suck warm air from the room to take it to the air conditioning condenser.

- Transfer grilles. In newer homes, you might have transfer grilles above the doors. These exist because the property only has one return duct per floor, so they allow air to flow properly when the doors are shut. You can check out this video for an explanation.

Why Do Air Vent Types Matter?

So, why does this matter? The simple answer is that some solutions won’t work for certain types of vents. For example, transfer grilles will need different soundproofing methods than extensive return ductwork. I’ll mention below which type of air vents each solution will work with.

Why Are Vents Noisy?

Vents themselves aren’t noisy, but they’re almost perfectly designed for transferring noise from one space to another. Some of the main sources of noise that travel through air vents include:

- Noise coming from outside (such as fan noise, outdoor noise pollution, etc.)

- Sound transferring from one room to another, such as talking, TV, music, etc.

- Air pressure as air moves through the ductwork. This creates noise, which can be both airborne and structure-borne.

Another issue we must consider is flanking noise. This is when sound travels indirectly from one space to another, rather than directly through the separating material. Whereas sound passing through a wall would be structure-borne, sound passing through HVAC ducting would be flanking. As such, even the most soundproof walls could allow sound transfer as flanking noise.

Factors Influencing Noise Traveling Through Vents

Perhaps a more important discussion is what factors influence noise traveling through air vents. To an extent, even minor noises can be annoying if your vents are designed in a way that amplifies sounds or creates a lot of echo.

Air vent factors that influence the pitch and volume of noise pollution include:

Number of Return Ducts

As mentioned above, it’s becoming increasingly common for homes to have 1 return vent per floor. While this is fine for saving cost, it can result in louder, higher-pitched noise.

This is because a single return vent (rather than 1 per room) can lead to a lack of air. In turn, this increases pressure and velocity of the moving air, which creates more noise. Several return vents mean more air is traveling around the system, so pressure drops.

Obstructions

Similarly, obstructions within the HVAC system – such as dust in filters or debris in the ductwork – can increase air pressure, again resulting in higher-pitched sound.

Air Vent Shape and Material

When ductwork travels around a corner, you either use 45- or 90-degree elbows. Fewer bends mean sound waves can travel more easily, whereas more bends can lead to more echo (but also more expended energy) as the sound waves bounce off the surfaces.

Unsurprisingly, metal is one of the worst materials for quiet ductwork, as it’s a good conductor of sound. This means sound can be heard more easily because metal has very bad absorptive, blocking and sound dampening properties.

Fan Speed and Static Pressure

I’ve discussed this numerous times, but any electric device that moves air will make noise. There’s a direct correlation between fan speed and sound level: faster means louder. But fan size also matters because smaller fans must spin faster to move comparable amounts of air.

Then we must mention static pressure. In short, it’s resistance to the flow of air through the HVAC system, measured in water columns (w.c.) or Pascals. Higher static pressure means more noise.

9 Ways to Soundproof Air Vents

Using this information, let’s jump into the best options for how to soundproof air vents. Some are more practical than others depending on your budget, experience level, access to HVAC systems, etc. But hopefully you’ll find at least one practical solution!

1. Line Ductwork with Acoustic Foam

Acoustic foam provides sound absorption for airborne noise. Sound waves get trapped in the foam’s open-celled structure and expend their energy. As such, acoustic foam is a viable solution for reducing sound traveling through HVAC vents. You can get duct liners, but acoustic foam is better for this job.

This solution will be most practical for supply vents because of where we’re installing it. Unscrew the supply vent grille and line the inside of the duct with acoustic foam, ideally as far back as you can reach.

Stick it down using a small amount of spray adhesive and make sure you line all sides of the duct. The purpose is to absorb sound waves that have traveled from outside before they reach the room. Although it won’t completely soundproof the vent, it’ll reduce echo and reverb from sound waves that have bounced around the duct.

2. Cover Transfer Grilles

Soundproofing transfer grilles is relatively easy, although the solutions aren’t permanent. The easiest way to reduce noise traveling through them is to cover them with an absorptive or sound-blocking material.

The 2 most practical options are soundproof blankets and soundproof curtains. Check out my articles linked here for some of the best options.

Both these products also work for reducing sound transfer through the door itself. Just make sure you hang the blanket or curtain high enough that it also covers the transfer grille. Of course, you’ll have to move the blanket or curtain every time you want to use the door!

Another downside to this solution is that the curtain will prevent the cool (or warm) air from circulating effectively in the room. Therefore, it’s a good idea to leave enough clearance between the vent and the curtain, so air can flow around it.

3. Use Flexible Ducts

If you’re willing to do a bit of extra work, replacing your current ductwork with flexible ducting is a viable solution. Using a flexible duct means the sound waves have more surfaces to bounce off, causing them to expend their energy faster.

This’ll only work for supply ductwork, though, as it won’t make a difference to whooshing sounds in the return ducts. Also, flexible ducts are more susceptible to damage, and small holes could lead to sound leakage.

Unsurprisingly, this is a pretty big job. It’s potentially worth the effort if you’ve got a problem with noise traveling in from outdoors but it won’t affect noise created on the flexible duct inside.

4. Clean Vents and Ductwork

Obstructions within the HVAC system (both return and supply ducting) can unnecessarily increase air pressure. An easy way to fix this is to clean your HVAC system.

You can clean the supply and return vents yourself. Just unscrew them, use a vacuum cleaner, and then wash them if necessary. This’ll get rid of dust and debris that could be creating pressure issues, which can lead to noisy air vents.

In theory, you can clean immediately inside the ductwork with a vacuum cleaner, too. But you won’t be able to reach too far in, so it might be worth calling a professional HVAC cleaner. A lot of companies will clean HVAC systems as part of their annual service, so this is worth bearing in mind.

Also, make sure you change or clean the HVAC system’s air filter. It’ll either be in the return air vent or the blower compartment before the air reaches the cooling unit. You should check it once a month, and most need changing every 3 months or so.

5. Build a Sound Maze

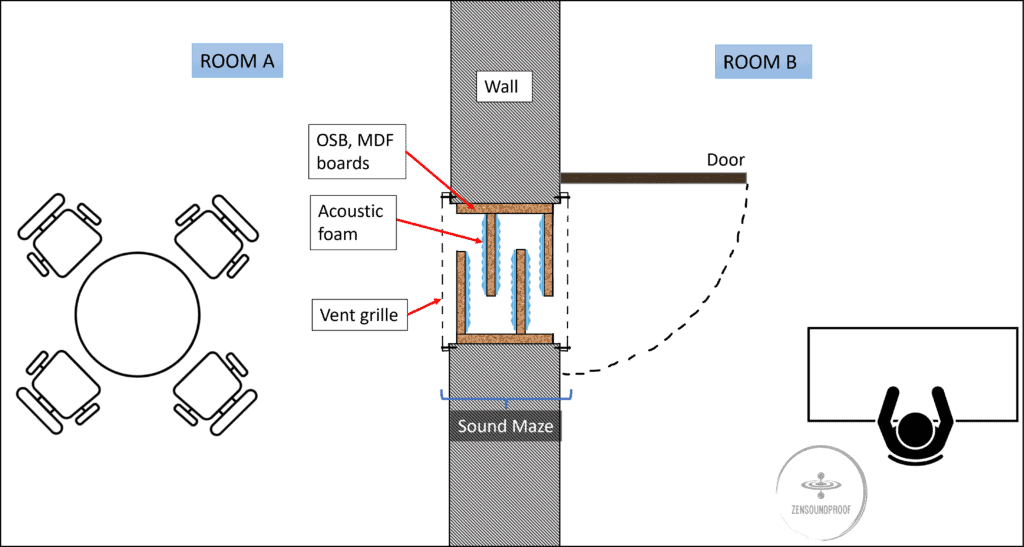

A sound maze is a fairly simple setup that involves adding more surfaces for the sound waves to bounce off. Lining these surfaces with absorptive material will make this even more effective.

Sound mazes work well to prevent the speaking tube effect. In other words, a sound maze will cut down airborne noise (voices, TV sounds) traveling from one room to another through the ductwork.

As such, sound mazes work best for transfer grilles above doors. You can check out this video for a visual guide on how to make one. In theory, sound mazes can be installed in supply ducts or return ducts, but doing so would increase air pressure in the system, which in turn would mean more potential noise. So, it’d be somehow counterproductive.

Transfer grilles can be considered very short ductwork as they are simple wall pass-throughs. Therefore, adding a maze in transfer grilles won’t generate additional noise from pressure differences.

To build a sound maze, you’ll need:

- OSB, plywood, or MDF

- Acoustic foam or insulation foam roll

- Spray adhesive or hot glue

The steps are as follows:

- Measure the height and width of your air duct (after removing the vent).

- Cut 2 pieces of wood to the height of your duct and to the desired depth.

- For the maze itself, cut pieces of wood to the width of your air vent minus 30%. For example, if your vent is 10” wide, the pieces of wood should be 7”.

- Cut at least 4 pieces of wood to this size. The more you can add, the better.

- Cover each one in sound absorptive material. Acoustic foam will absorb more sound, but compensate for the fact that it’s 1” thick at least. Leave one short side uncovered, so you can stick it to the support.

- Stick the long pieces to your support pieces, alternating between sides.

- Once everything is dry, install these in your ducts simply by sliding them into place. Provided your measurements are correct, there’s no need to fix them down.

Helpfully, we also have a sound comparison for the sound maze – it yielded a 5dB reduction of sounds perceived between one room to another. Although this isn’t massive, it’s good enough for such a thin vent. It would be even better if the builder used a specific soundproofing material rather than a Styrofoam sheet.

A sound maze is probably one of the best options for soundproofing transfer grilles to reduce noise from the communicating room. That said, it won’t be super helpful on return vents, as the issue in these is mainly pressure related.

6. Check Your Return Vents

Other than cleaning your return vents, there are some other things you should consider to make them quieter. These include:

- Making sure they’re open. If you have more than one return vent per floor in your home, make sure they’re all open. Closed vents will reduce air flow in the system and increase pressure.

- Making sure they’re not obstructed. While the impact is minor, obstructing return vents with furniture will lead to the same issues. Ensure there’s clearance around return vents of at least a foot.

- Fit a fixed bar grille air vent cover. Also known as a high velocity grille, they’re more open than standard adjustable or stamped face grilles, meaning air can flow more easily.

Along with increasing air flow, these solutions can reduce static pressure, both of which result in quieter air movement (in theory).

7. Build Soffits

If your noise issue relates to exposed ductwork – such as in a basement or garage – the easiest option is to build a soffit. In short, this is a box around the ducting that you can then line with sound blocking or insulating materials. We could also consider this option to be a sound baffle, but both names mean roughly the same thing here.

It’s a more involved project than a sound maze, so I recommend watching this video for a full guide on how to build a soffit.

Once you’ve got the frame, you’ll want to add sides made from MDF or plywood. You can add a layer of acoustic foam inside the frame for sound absorption, and a layer of mass loaded vinyl on the outside for sound blocking.

You can also insulate the ductwork using a variety of materials. Thermal duct insulation (such as this) won’t make much difference to noise transfer because it’s too thin. However, using something like rock wool slabs or InVent slabs will provide both thermal and acoustic insulation. Depending on the size of your ductwork, you could install this inside or outside.

Note, this won’t make a difference to noise pollution coming through the vents in your rooms. Instead, it’ll reduce sound leakage in areas where ductwork is exposed.

8. Call a Professional

If you can’t locate the source of the excess noise, it might be worth calling a professional HVAC technician. Ideally, you should have your HVAC system serviced annually, and most technicians will also clean it. But if you’ve noticed an issue, call someone in for an inspection.

9. Install a New HVAC System

If you’ve tried cleaning ductwork and fitting sound mazes and it hasn’t done what you wanted, it might be time to replace your HVAC unit. Excess noise can often be a sign of a larger problem, even if it’s just that your system is old and not working as efficiently. The easiest solution for noise reduction is to get a new AC unit.

Luckily, there are plenty of quiet central AC units out there. Check out my article on quiet AC for a roundup of some of the best. They can be as quiet as 55dB, which is a lot less than the normal 70-80dB of an AC system!

Related HVAC Duct Soundproofing Questions

Can You Soundproof Air Vents?

The only way to truly soundproof an air vent is to remove them completely and replacing them with drywall. Unfortunately, this isn’t practical if you want to use the HVAC system. As such, it’s impossible to fully soundproof air vents if you want them to still transfer air because sound and air follow similar transfer patterns.

Can You Hear Neighbors Through Vents?

If you and your neighbors share a HVAC system, you might be able to hear them through the vents. This is because sound travels from their vents into the ductwork and out of your vents. This is the principle of a speaking tube. To prevent this, simply add some acoustic foam or a sound maze just inside your vent and it should reduce the noise pollution.

Why is My Return Vent So Loud?

Your return vent is probably loud because of increase air pressure due to reduced airflow. To fix this, try cleaning your vent covers and checking for obstructions within the ductwork. If that doesn’t help, you might need high velocity vent covers.

Is it OK to Cover a Return Air Vent?

The short answer is that it’s not OK to cover a return air vent. Covering or blocking the vent will stop air from returning to the cooling unit of your HVAC system. Over time, this’ll lead to reduced efficiency and premature system failure, simply because it can’t work properly. Replacing or fixing a HVAC cooling unit is far worse than a noisy return air vent!

One of the suggestions above recommends covering transfer grilles above doors. This has less impact than covering HVAC air vents because there isn’t the same kind of air pressure issue. Provided you leave clearance in front of the transfer grille, it’ll be fine. But covering an HVAC air vent will be counterproductive because of the increased pressure.

Final Thoughts

Hopefully, this article has given you some inspiration for how to sort your noisy HVAC vents. Most solutions rely on absorption because we’re dealing with airborne noise and we need to maintain airflow. Provided your system is working properly (but is just noisy), sound absorption should mitigate the issue.

Do you have any other suggestions for how to reduce noise pollution in a HVAC system? If so, I’d love to hear your thoughts in the comments below!

1 thought on “9 Steps How to Soundproof Air Vents: Deal with Your HVAC Noise”

Ludovic, thanks for sharing such valuable information! The HVAC systems and related equipment in buildings are a primary source of vibration and noise. Thus, soundproofing air vents are required to restore peace and tranquility. I think soundproofing standalone air vents is doable by covering them with soundproofing materials or replacing them with drywall. Soundproofing the unit is possible using duct liners and sound baffles.