In my career as an engineer, I’ve spent a lot of time designing and implementing soundproofing setups. More clients than I can count have asked me, does soundproof foam work to block noises? Here’s the quick answer I typically give them:

Soundproof foam, also called acoustic foam or soundproof squares, doesn’t block noises, as this isn’t its purpose. It works on the principle of absorption rather than blocking. While both are necessary to properly soundproof a space, they’re drastically different concepts.

Below, I explain this distinction in more detail. And, through my practical knowledge of engineering, I detail why soundproof foam doesn’t block noise.

Why Acoustic Foam Doesn’t Block Noise

I’ll get this out of the way: soundproofing foam is a misnomer for this product. A far more accurate name is acoustic foam. This is because the foam doesn’t soundproof. Rather, it helps absorb sound echoes passing around a room.

So, when we ask, do soundproof squares work, the answer will always be no. We’re asking the wrong question here. Instead, we should be asking, how does soundproofing foam work? Doing so will help us understand why acoustic foam doesn’t block noise.

Sound Blocking vs. Absorption

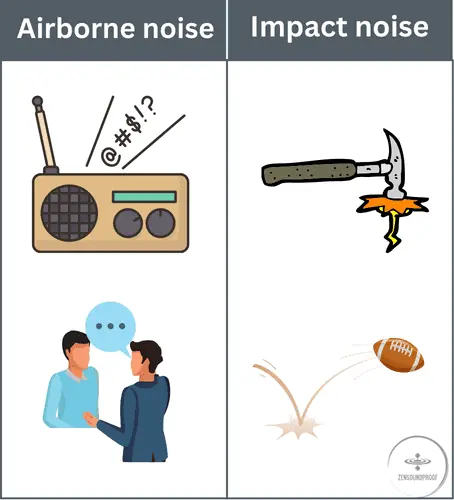

First, let’s briefly cover sound waves. They’re vibrational energy that travels through:

- The air (such as a TV or someone talking)

- Or solid structures (a hammer striking a nail in a wall)

Sound energy moves from the source to our ears, making particles in the medium (air or structure) vibrate. Depending on the medium of travel, they’re called airborne noise or structure-borne noise.

Sound waves occur at different frequencies – from high to low – that require different blocking methods.

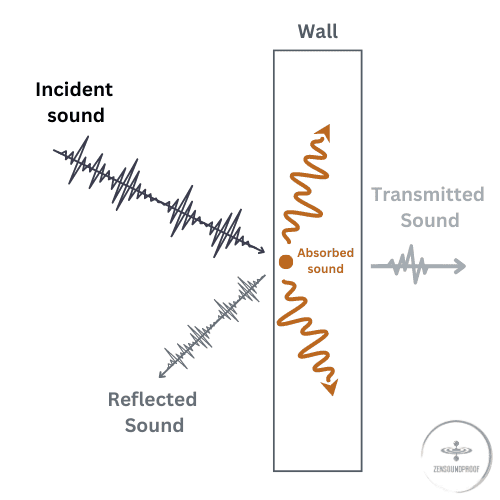

This is because low frequency sounds have a longer wavelength than high frequency ones. In turn, it means they expend less energy when traveling because they don’t need to make things vibrate as much. It’s why you can hear bass frequencies more easily through structures. When sound waves make contact with a surface, some waves will travel through while others will reflect off. The process of waves traveling through is called transmission. On the other hand, the waves that reflect off are what create echoes and reverberation.

Based on my experience, few people realize that these processes require different methods of treatment. This is where sound blocking and sound absorption come in.

Sound Blocking

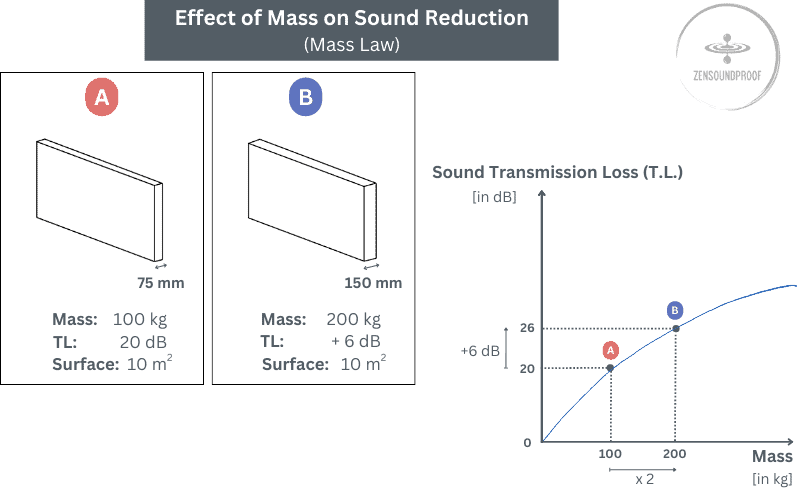

Sound blocking, as the name suggests, involves stopping a sound from passing through a structure. You’re literally blocking it from being able to transmit. The most effective way to do this is by adding mass, as this makes it more difficult for sound waves to make the structure vibrate.

This is what’s known as Mass law, or Berger’s law. According to Berger’s law, the effect of sound insulation on a wall increases by 6 dB for every doubling of the wall’s mass. Another way of explaining it is to say that the higher the density (mass) of a material, the less likely it is to vibrate when impacted by sound waves.

Sound Absorption

Sound absorption, on the other hand, involves absorbing sound waves to prevent them from reflecting off a flat and hard surface. Sound waves are energy (vibrational energy), which is expended by making particles in a wall or the air vibrate.

Absorptive materials are essentially sponges. They’re porous materials that transform vibrational energy into another form, typically heat. Soundproofing foam works by letting waves enter the porous material and expend their energy trying to make it vibrate. They’re unable to bounce back out of the porous material and so “waste” their energy, which is converted into heat.

Think of the difference this way. Imagine you and a friend are having a conversation through a wall. You can hear each other, sure, but not very well. Now imagine having the same conversation through a wall made of sponges or foam. You’ll be able to hear each other much better. In my experience, this is one of the easiest ways to explain it to people.

Does Soundproof/Acoustic Foam Even Soundproof?

As mentioned, acoustic foam doesn’t soundproof. Soundproofing panels are designed to absorb sounds rather than proof a space against them. However, it can be really quite effective at the job it’s actually designed to do.

We’ll start to get a bit more technical now by using some industry metrics. To understand how soundproof foam works, we need to know about NRC and STC.

NRC

NRC stands for Noise Reduction Coefficient.

NRC refers to how effectively a product can absorb sound wave energy.

We express it as a decimal that refers to the percentage of acoustic energy the product absorbs. For example, soundproof foam with an NRC of 0.4 would absorb 40% of the sound and reflect the remaining 60% back into the room. The best acoustic foam can absorb 90% or more of a sound wave’s energy.

NRC is impacted by the material’s thickness and density, and the sound wave frequency. Thicker foam has a higher NRC than thinner products. Also, acoustic foam is typically better at absorbing higher frequencies than low ones.

STC

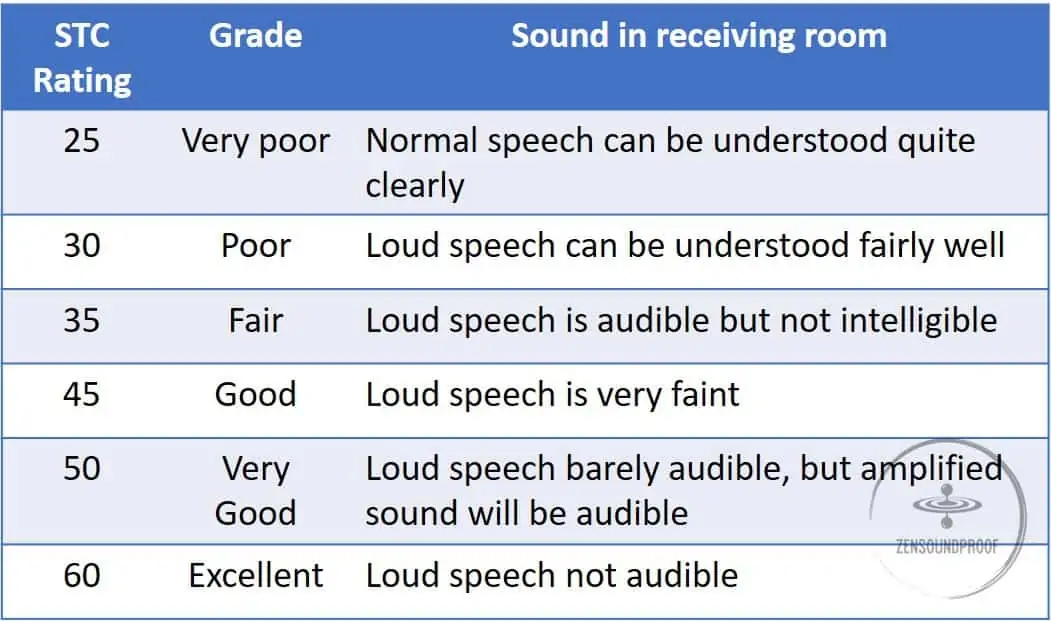

STC is Sound Transmission Class. It’s a metric used to determine how much a material attenuates (blocks/reduces the energy of) sound waves. For example, mass-rich materials like brick can have an STC rating of up to 55. On the other hand, acoustic foam has an STC of 10-20 depending on its thickness and density.

In a proper soundproofing setup, you want both NRC and STC. You need different materials for both, but acoustic foam is meant for sound management – making voices and music sound better.

| STC | NRC | |

|---|---|---|

Brick Wall  |

~55 | ~0.00 - 0.05 |

Acoustic Foam  |

~10 - 20 | ~0.85 |

As you can see from the table above, combining a mass-rich material like brick with acoustic panels gives you good coverage for both STC and NRC. Specifically, sound management refers to reducing echo and reverberation, also known as acoustic treatment. If you’d like to know more about reducing echo in a room, I recommend checking out my article.

How is Acoustic Foam Supposed to be Used?

Acoustic management is important in spaces where you need sounds to be clearer. For example, you’d want it in a home theater, concert hall, or recording studios. It helps make sounds less muddy/muddled because it prevents them from essentially overlapping on their way to our ears.

For a really good example of this in action, I recommend you check out this video from one of my favorite channels, Gamer’s Nexus, to see how foam panels helped in their studio.

Types of Soundproof Foam

All acoustic foam panels are made from an open-celled material that traps sound waves and prevents them from escaping. There are 4 main structure types of acoustic foam:

- Egg crate

- Pyramid

- Wedge

- Bass traps

I discuss these in more detail in my article on egg crate foam, so check that out to understand how they work. In short, different designs increase the foam’s surface area, giving the sound waves more surfaces to reflect off.

How to Install Acoustic Foam

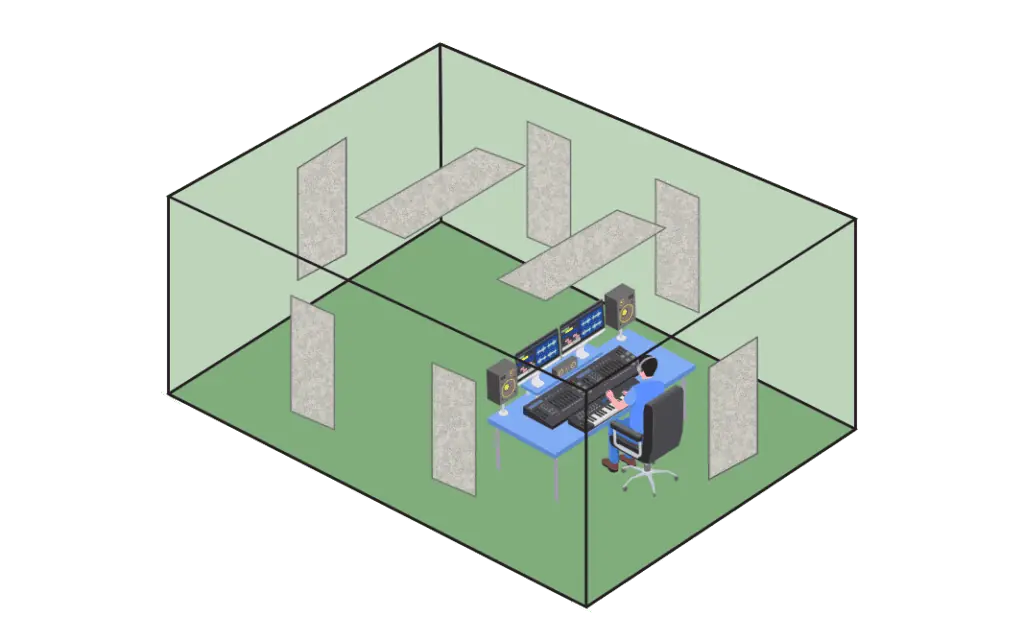

One of the most important aspects of acoustic foam is how (and where) you install it. My firsthand experience dealing with soundproofing clients has shown that many people think greater coverage is better. However, this generally stems from them confusing absorptive products with sound blocking materials.

Acoustic Foam

For standard acoustic foam, we must install it at the direct points of reflection. These are the areas on a wall directly opposite the noise source. Unsurprisingly, they’re the first points that sound waves reflect, so absorptive materials are most effective here for managing the room acoustics.

Although first reflection points will vary depending on your speaker/source setup and room layout, it’s pretty easy to find them. You simply need to follow a straight line from the speaker to the first wall and put foam there. After that, you need to address the second and third reflection points. Again, these will differ, but you can expect them to be the wall behind the speakers and possibly the ceiling. Overall, you can expect between 25 and 75% coverage of the walls and ceiling with acoustic foam.

The level of coverage you need depends on various factors, such as the number and placement of your noise sources and your listening area. For example, in a home streaming setup, you’ll only really need to cover the first point of reflection.

On the other hand, a recording studio would benefit from greater coverage because you need as little echo and reverb as possible. It ultimately depends on the room’s purpose and the sound quality you require.

Another example where you’d need greater coverage is a concert hall. This is because there isn’t just one noise source but many. As such, there are numerous reflection points, all of which need to be addressed for better quality sound.

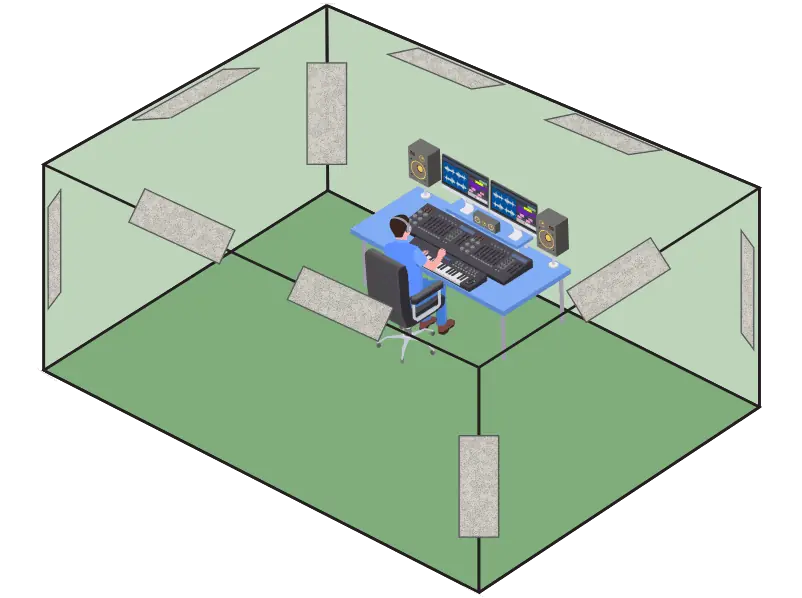

Bass Traps

Bass traps are specifically for bass frequencies, but they’re much easier to install as a result. They go in the corners of the room, as bass frequencies collect more easily here. You can check out this video for a clear guide on how to install bass traps.

Sound waves collect easily in the corners of rooms because they provide ideal reflection spaces. This is due to the close proximity of the walls (and possibly the ceiling too). Trihedral corners (wall, wall, and ceiling) are the perfect setup to reflect sound.

It’s most noticeable with bass frequencies, as their longer wavelength can travel further and more easily than higher frequencies. These factors combine to make bass frequencies collect in room corners.

However, you don’t need to fill every corner floor to ceiling with bass traps. One in each corner at the same level as your noise source will be enough to counteract low frequencies.

Alternatives to Acoustic Foam

There are numerous other types of foam that you’ll come across for soundproofing projects. However, these are typically designed for actual soundproofing rather than acoustic management.

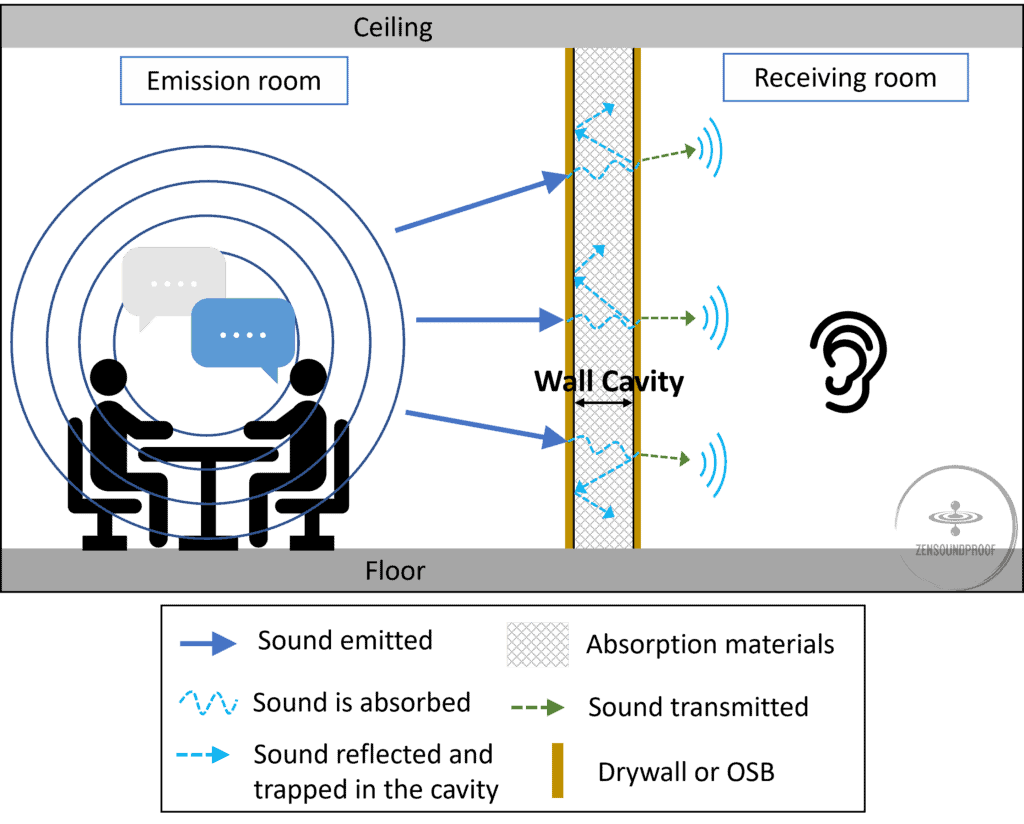

They achieve this by being denser than acoustic foam. While they’ll still absorb sound, they also block it by adding more mass. Another important distinction is that many of these products go inside a wall assembly, where acoustic foam wouldn’t be able to do much good. Some well-known examples are mineral wool (i.e., rockwool) and fiberglass. We can use these to improve a structure’s STC by filling the cavity between sheets of drywall with an absorptive material. This helps to reduce cavity resonance.

Cavity resonance is when sound waves enter the cavity within the wall and bounce around (resonate) off the surfaces. It can have quite a significant impact on the perceived loudness of a noise transmitting through the structure. As such, adding an absorptive material that’s thicker and denser (such as fiberglass) is useful for improving STC.

To understand the difference it can make, it’s best to compare the types of foam in a table:

| Fiberglass | Mineral wool | Acoustic Foam | |

|---|---|---|---|

|

|

|

|

| NRC | 0.9 - 0.95 | 0.7 - 0.9 | 0.4 - 1 |

|

STC Increase (Drywall + Staggered studs + Drywall) |

+2 STC Points | +3 STC Points | N/A |

As you can see, the main focus of rockwool and fiberglass is still on sound absorption. However, their density provides some sound blocking and deadening, which offers some improvement to STC ratings.

On average, consider an improvement of around 2-3 STC points if you use Mineral Wool or Fiberglass in a wall’s cavity.

There’s also the added advantage of thermal insulation, which relies on many of the same principles as acoustic insulation. Of course, it’s not our focus here, but it’s definitely worth mentioning.

Other Soundproofing Strategies

Your options for soundproofing a room can quickly become overwhelming once you see all the different products available. However, planning your soundproofing project doesn’t need to be difficult provided you understand the main principles and the best materials for adding these.

The most important thing to know is that you’ll get the best results by combining several (or all) the principles if you can. Each tackles a different aspect of sound transmission, meaning a combination is most effective.

So, other than sound absorption, some alternative soundproofing strategies include:

1) Adding Mass

There are a couple of different options for adding mass to an existing wall. The ones below do so without adding too much extra depth to the structure:

Drywall

There’s not much more to say here because I’ve already explained the principle of sound blocking in enough detail. However, to achieve a noticeable improvement to a structure’s STC rating, you’ll need to add some proper mass-rich materials.

For example, adding a layer of soundproof drywall can make a considerable difference. This is like a drywall on steroids: normal drywall with extra mass (such as mass loaded vinyl or rockwool) sandwiched in the middle.

One product, Quietrock, has an STC rating of 52-74, which is a massive improvement.

MLV

Another good product is mass loaded vinyl, which can have a standalone STC rating of 30 or above. This depends on its density, which goes up to 2 lbs. per square ft. Although expensive, it’s an easy-to-use product that delivers decent results.

2) Resilient Materials

A resilient material, generally speaking, is one that doesn’t transmit sound waves that pass through it. They have elastic or viscoelastic properties, meaning they return to their original shape and don’t transmit vibrational energy.

There are 2 main options for adding them to your soundproofing project:

On Floors

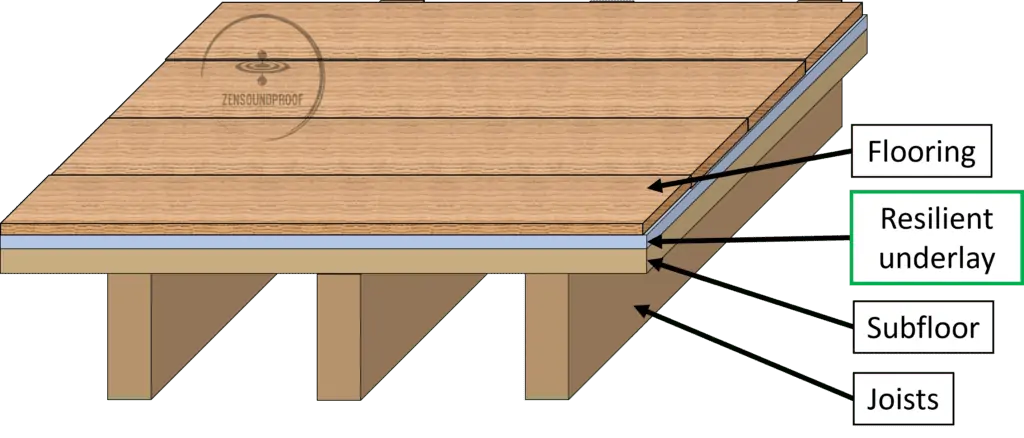

You can add resilient materials to your room in the form of carpet or hard flooring underlay, or as rug pads (more info here). As I explain in my article on soundproof underlays, these products primarily affect impact sounds.

The metric for this is Impact Insulation Class (IIC). Like STC, it measures how much a material blocks/attenuates sound waves, but it differs from STC in that it focuses on impact sounds rather than airborne ones.

While it, therefore, doesn’t have much effect on STC ratings, IIC is as important as STC for improving a room’s overall soundproofing. To know more about how to address IIC improvement (dealing with structure-borne noise), you can check out my article on how to soundproof floors.

In the Walls and Ceilings

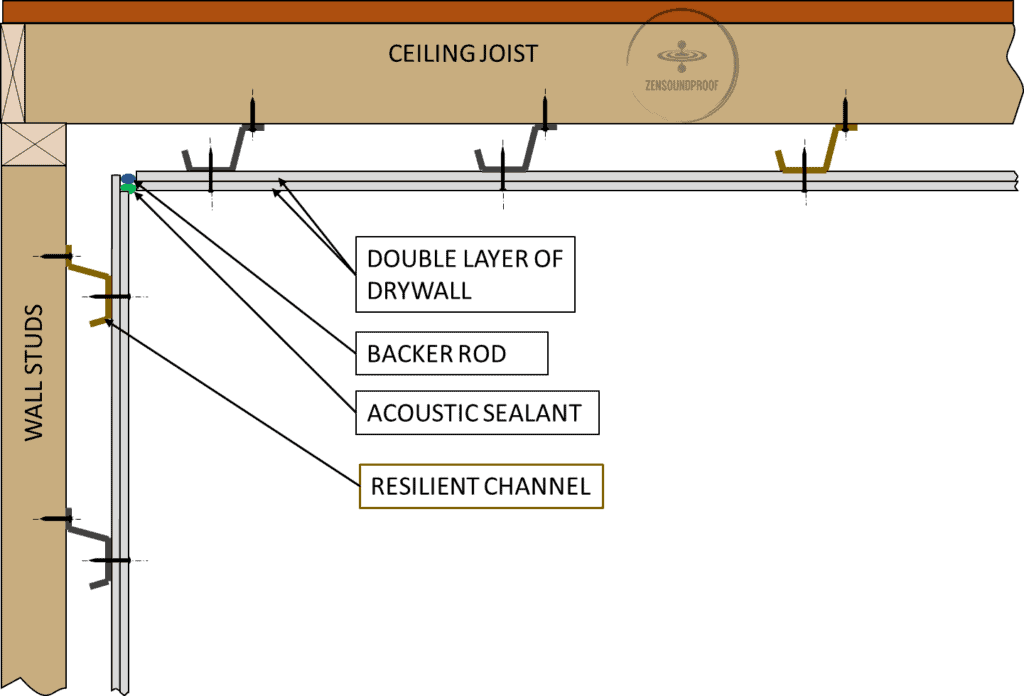

For airborne sounds (and, to an extent, impact sounds) transmitting through walls, we have resilient channels. They rely on the soundproofing principle of decoupling, which is the process of mechanically separating 2 sides of a structure.

A resilient channel is fixed to the wall studs. From it, you hang drywall on resilient sound clips (or similar). They have a small rubber washer around the screw hole that effectively reduces sound transmission. While they’re not as effective as full mechanical isolation, they’re much easier to install and provide very good results.

Resilient channels are arguably the biggest soundproofing project out there. However, in my experience, they deliver the kind of results you need in rooms where actual soundproofing is a priority. They’re expensive, but the outcome speaks for itself.

Final Thoughts

I hope this article has clarified some of the myths around acoustic foam and has answered the question, do soundproof squares work to block sound?

Simply put, acoustic foam isn’t meant to block sound: it’s far too thin and light to be effective at this. However, it’s ideal for sound absorption and acoustic management within a space, seeing as this is its purpose.

The bottom line is that you’ll want to use acoustic foam alongside sound-blocking materials to address the main aspects of a soundproofing project.

Do you have any other tips to share, or any myths about acoustic foam to dispel? I’d love to hear from you below in the comments.